A.L.P.’s Lindy® and Lineman™ Post-Top Optics Offered in Two Pieces

Simple solution saves time, freight, and cost

A.L.P. offers two of its Industry-leading post-top optics in two pieces to simplify installation and save you money.

Freight costs can be lowered dramatically, with refractor tops and caps nested and shipped separately, cutting the weight and size of bulkier shipments. Assembly is easy and can be done on-site without tools.

Lineman™ also is offered with optional caps and finials, allowing you to expand your product offering easily and inexpensively.

In addition to saving money, the Lindy® and Lineman post tops outperform other one-piece solutions for roadways, walkways, parks, and residential outdoor lighting. Their outstanding features and benefits include:

• Visually pleasing

• Compatible with HID or LED

• Lower glare

• Durable

• UV stable

• Impact resistant

• Material choices

• 8” or 9” necks

• Optional accessories

A.L.P., Acrylic, Clear Acrylic, Clear Polycarabonate, HID, injection molding, LED, LexaLite, Lindy, Lineman, Lumieo Acrylic, Post Top, refractor tops, residential outdoor lighting, UV Stable

New Post-Top Combinations to Expand Your Product Line

Fewer SKUs, Cheaper Freight, Lower Overall Cost

A.L.P.’s newest post-top lighting innovation allows our model 401 Lineman™ top and cap to be used with our industry-leading model 425 Lindy® bottom, so you can add to the variety of your traditional street and area lighting while cutting costs and keeping SKUs to a minimum.

The secret is in the design of Lineman’s injection molded top and cap. Using a snap-fit feature, it is attached in the field without tools. The top and bottom optics are shipped separately, dramatically reducing freight costs up to 70 percent versus pre-assembled post tops and eliminating the need—and cost—of attaching clamp bands.

This interchangeable option combines the look and performance of the Lindy with the value of the Lineman, adding variety to your product offering with the most economical, environmentally friendly approach. Other new options include new black acrylic tops for some Lineman and Lindy configurations.

All Lindy and Lineman acrylic post tops come with a 10-year warranty against discoloration. Why wait when you can add variety and lower costs with a classic post-top aesthetic and superior performance?

A.L.P., Black Acrylic, injection molding, Interchangeable, LexaLite, Lindy 425, Lineman 401, Lumieo, Polycarbonate, Post Top, Post-Top Combinations, Post-Top Configurator, Snap-fit, Street and Area Lighting

Press Release: A.L.P. Introduces the Sentry® Barricade™ Lens for Outstanding Vaportight Performance

(Niles, IL) A.L.P. Lighting Components is pleased to announce the introduction of Sentry® Barricade™, a new 4-ft injection-molded low-profile lens. It is the newest addition to A.L.P.’s line of rugged lenses for the flagship Sentry® Series enclosed and gasketed fixture kits. Featuring a contemporary look and outstanding performance, the new lens modernizes the Sentry Series line while maintaining the existing benefits of robust construction and a large compartment size.

Designed by the injection molding experts from A.L.P. LexaLite®, Sentry Barricade’s molded-in texture offers superior lamp hiding. In addition, a new gasket compression rib results in superior sealing for extreme environments.

The Sentry Barricade lens is available in clear acrylic, Lumieo® (frosted acrylic), and clear polycarbonate. Regardless of the light source, the clear and Lumieo options provide visual comfort while maintaining high efficacy. The clear polycarbonate version will stand up to applications requiring impact resistance and is a more economical choice than A.L.P.’s current thermoformed offering.

Suspended vaportight Sentry enclosures are suitable for wet, damp, dusty, and cold applications such as parking garages, car washes, industrial buildings, and horticultural spaces. Samples are available now.

A.L.P., Barricade, Barricade Lens, car washes, Clear Polycarbonate, damp applications, dusty applications, gasket compression rib, Gasketed Enclosure, horticultural spaces, industrial buildings, injection molding, LexaLite, Lumieo Acrylic, parking garages, Sentry Barricade Lens, Sentry Series, superior sealing, Vapor Tight, vaportight, wet applications

Meet the Team: Kurt Puffpaff

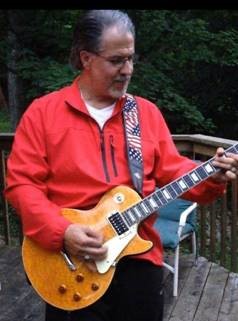

Kurt Puffpaff ROCKS! Though in Kurt’s case, we mean that quite literally. A musician and music aficionado, Kurt plays guitar, sings, and is a huge fan of ‘70s rock bands like AC/DC, Styx and Led Zeppelin. He also writes and records his own original tunes, played on his favorite Birdseye Maple Les Paul guitar. Besides his love for music, Kurt is an avid outdoorsman and a die-hard Kansas City Chiefs fan.

Born and raised in Charlevoix, Michigan, Kurt has moved around the Midwest for his career before returning to his hometown a few years ago and settling with his wife Diane and their four sons, aged from 11 to 22.

Kurt is currently the National Sales Manager for A.L.P.’s custom optical products, but he has been in the lighting industry since 1993. He started his career as a territory manager for LexaLite (now part of A.L.P.) where he learned the business from the ground up, even delivering a few orders by truck when the business depended on it. Drawing on his decades of expertise in injection molding, Kurt can answer almost any molding question that comes his way. You are also invited to pick his brain on classic rock, football, or hunting.

A.L.P., Charlevoix, injection molding, Kansas City Chiefs, Kurt Puffpaff, Les Paul Guitar, LexaLite, musician, National Sales Manager, outdoorsman

Press Release: A.L.P. Produces PPE Face Shields for COVID-19 Health Care Workers

Joining the fight against the COVID-19 pandemic, the injection molding team at A.L.P. LexaLite’s Charlevoix, MI facility mobilized to design and manufacture Personal Protective Equipment (PPE) face shields for front-line health care workers. They rapidly reorganized tooling and manufacturing functions to support this critical need, and they expect to have the first production models coming off the presses within days.

The company was initially approached by Charlevoix Hospital, looking for PPE. While primarily a manufacturer supplying components for lighting fixtures, A.L.P. has several customers in the health care sector. The team drew on its knowledge of health care requirements and standards to quickly design and tool the face shields in an unprecedented 10-day turnaround.

When in full production, A.L.P. can produce approximately 1400 face shields per day, and they plan to sell them at cost. “We will make them as long as they are needed,” states Steve Brown, CEO.

“This is one scenario I didn’t see coming,” Brown adds. “The COVID-19 crisis is tragic, yet it shows us what we can accomplish together when needed,” he observes. A.L.P. is not alone, as manufacturers all over the country are making similar efforts.

The A.L.P. face shield has some unique features. The plastic shield snaps onto a headband, and the shield is disposable. So, the caregiver can use the same headband throughout the day and simply snap on a new shield for each patient.

A.L.P. continues to operate during this crisis as an Essential Business, supplying into vital infrastructure such as construction, health care, transit, and government. The company has adjusted its practices, with the health and safety of employees, families, and communities as a top priority. The A.L.P. staff is working remotely when possible. All manufacturing locations have implemented additional measures to ensure safe distancing of employees, such as adjusting schedules, spacing equipment, and reorganizing meeting and break room spaces.

Charlevoix, COVID-19, disposable shield, Essential Business, headband, Health Care Workers, injection molding, LexaLite, Personal Protective Equipment, PPE Face Shields, tooling

Press Release: A.L.P.’s Charlevoix Facility Achieves ISO Certification

(Niles, IL) -A.L.P. is pleased to announce that our Charlevoix, MI facility has been certified to ISO 9001:2015 by DNV GL. A.L.P.’s Dickson, TN facility has been certified to 9001:2015 since November 2018. A.L.P. has had a long-established Quality Management System, and these certifications affirm our commitment to effective manufacturing and business practices. “We welcome new and existing customers to audit our facilities,” offers Tom Barnes, VP and Business Unit Manager. “We hope these certificates offer an extra measure of confidence in our abilities,” he adds. A.L.P.’s Charlevoix and Dickson facilities produce LexaLite® brand injection molded components. A.L.P. has also significantly expanded its injection molding capacity in the Monterrey, Mexico plant.

A.L.P. LexaLite is an industry-leading provider of injection molded components in thermoplastic and optical silicone. Long recognized for designing and manufacturing innovative optical lighting components, A.L.P LexaLite also serves markets such as Medical, Automotive, Signage, Point of Purchase, Electronic Equipment, Appliance, and Mass Transportation.

A.L.P.’s team of experts provides specialized services from product design and engineering to tooling and prototyping, product testing and contract assembly. Production capabilities include press sizes ranging 88-1650 tons and industry-leading capabilities in secondary operations such as UV coating and laser cutting. Committed to innovation and responsive to market requirements, A.L.P. LexaLite also offers unrivaled capacity in optical silicone injection molding and edgelit injection molding.

A.L.P. is an international leader in the design, manufacturing, and distribution of lighting components and components for other technical industries. We offer the industry’s most comprehensive line of products for OEMs and the aftermarket. For custom projects, our unique “360° Solutions” suite of custom services enables us to collaborate with customers at every stage of a product’s life cycle. Our core commitment is to provide superior service and product performance to every customer.

Charlevoix, Edgelit, injection molding, ISO 9001:2015, ISO Certification, MI, Optical Silicone, Press Release, Thermoplastics