A.L.P. Monterrey Earns ISO 9001:2015 Certification, Enhancing Quality and Value for Customers

A.L.P. is proud to announce that our Monterrey, Mexico manufacturing facility has achieved ISO 9001:2015 certification, a globally recognized benchmark for quality management systems. This certification underscores our unwavering commitment to delivering reliable, high-quality products and services to our customers. For customers across lighting, medical, automotive, appliance, and mass transportation industries, the certification offers added assurance that A.L.P. Monterrey meets rigorous international standards for quality, efficiency, and continuous improvement.

“This is more than a milestone—it’s a reflection of our team’s dedication to operational excellence and our strategic focus on being a trusted partner to OEMs,” states Adam Mayse, A.L.P.’s President and COO.

The Monterrey facility is strategically located in one of Mexico’s key manufacturing corridors, offering proximity to major customers and suppliers. Capabilities at this location include injection molding, compression molding, optical silicone molding, and metal fabrication.

Congratulations to the entire Monterrey team for their hard work and focus in achieving this important certification—another step forward in strengthening A.L.P.’s value to our customers.

Why Silicone is Revolutionizing Optical Molding

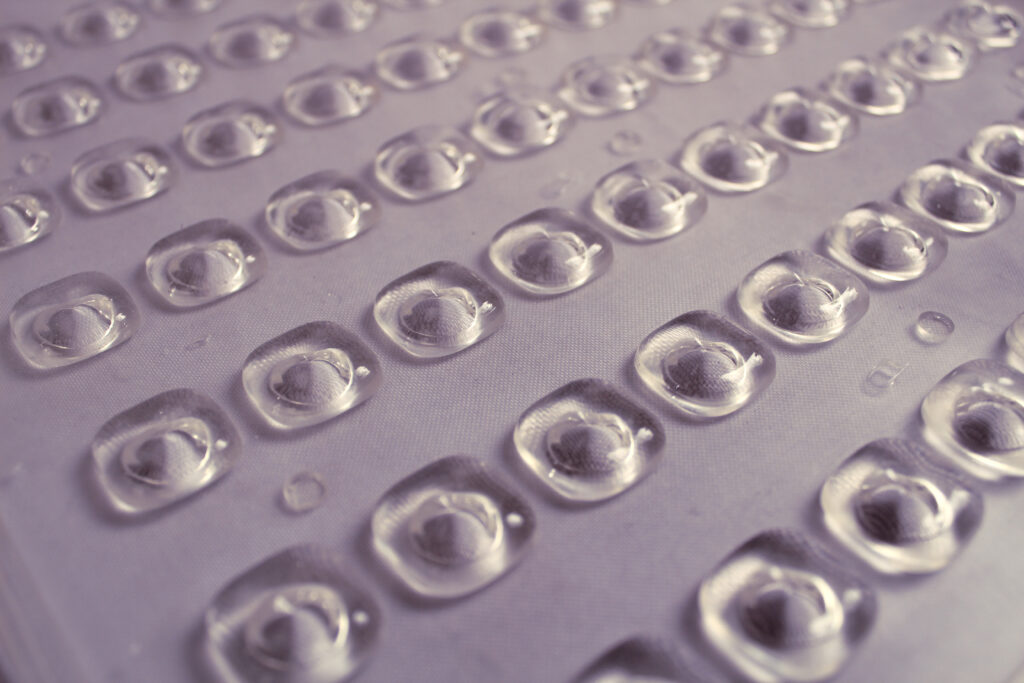

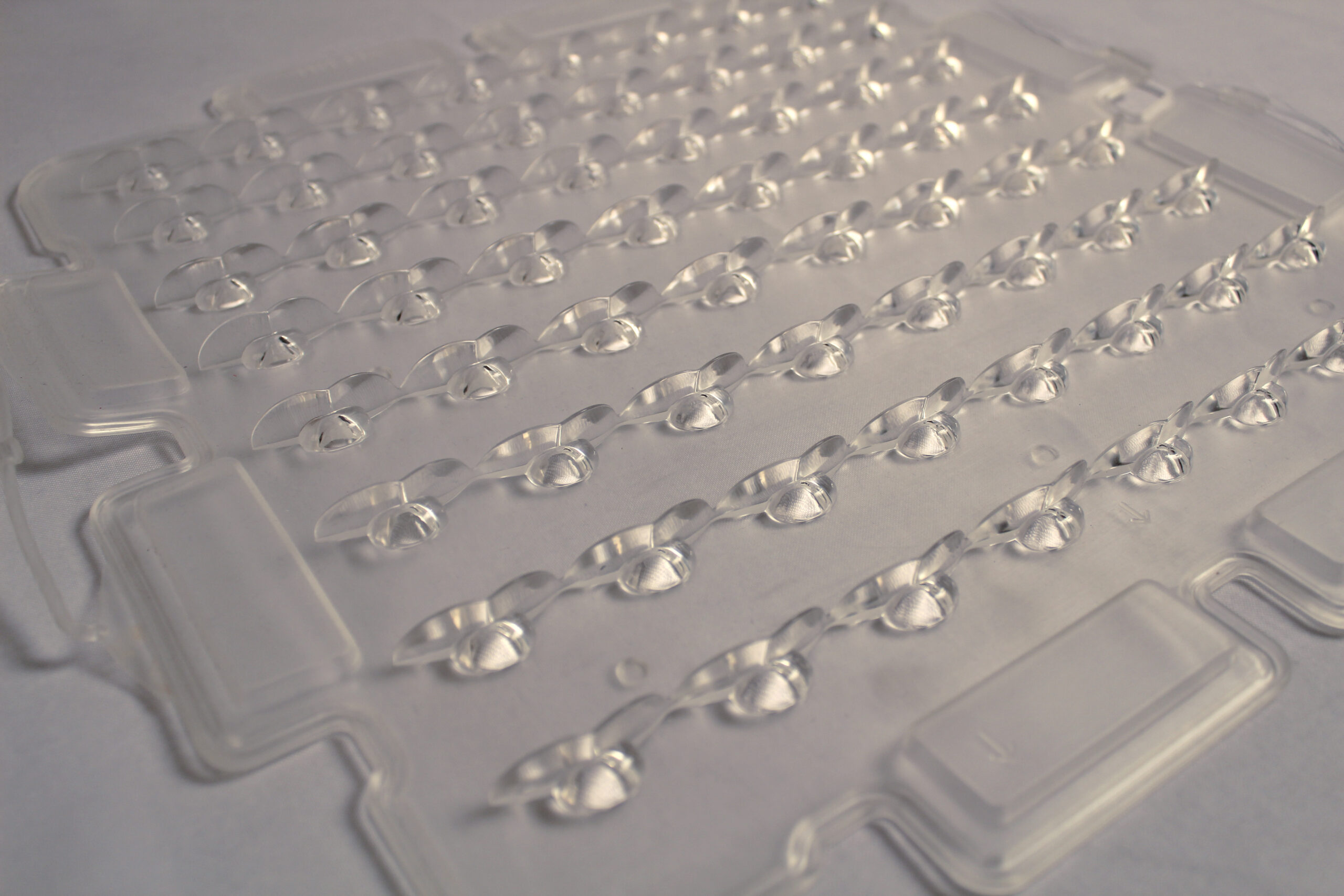

In the world of precision optics, choosing the right material for your molding project can significantly impact performance, durability, and efficiency. Optical silicone molding is emerging as a game-changer, offering advantages that surpass traditional thermoplastics. A.L.P. provides industry-leading expertise in optical silicone molding, combining advanced equipment, tooling, and optical engineering to deliver high-quality solutions. Our in-house photometry lab enables real-time evaluation of first samples, ensuring optimized results from concept to production.

The Advantages of Optical Silicone Molding

When selecting materials for optical applications, Moldable Optical Silicone (MOS) stands out due to its unique properties. Here’s why optical silicone is revolutionizing the industry:

Superior Optical Clarity and Light Transmission

• Optical silicone provides greater than 91% light transmittance, ensuring maximum efficiency in lighting and optical applications.

• A refractive index of 1.41, it enables high-performance optical designs.

Exceptional Moldability and Precision

• Its low viscosity allows for excellent mold replication, capturing fine details with precision.

• Unlike thermoplastics, silicone requires low clamp tonnage, reducing production costs and complexity.

• Negative draft (undercut) features can be achieved with optical silicone, making it highly versatile for complex geometries.

Unmatched Durability and Environmental Resistance

• Silicone offers an exceptional continuous service temperature range from -45°C to +200°C, maintaining stability in extreme conditions.

• Most optical silicone grades are immune to UV degradation, ensuring long-lasting performance without yellowing or material breakdown.

• Exceptional impact resistance makes it ideal for rugged applications.

Versatility in Molding and Integration

• Insert molding capabilities with plastic, metal, and glass allow for integrated component manufacturing.

• Silicone expands when molded, allowing for thicker wall sections with no sink marks, a common issue with thermoplastics.

• Its ability to provide self-gasketing and self-mounting functionalities reduces the need for additional components and assembly steps.

Why Choose A.L.P. for Optical Silicone Molding?

A.L.P. stands at the forefront of optical silicone molding, leveraging cutting-edge equipment, innovative engineering, and a dedicated in-house photometry lab. Our expertise ensures:

• Rapid prototype development and testing

• Precision molding with complex geometries

• Reliable, high-performance optical solutions for demanding applications

If you’re considering optical silicone molding for your next project, A.L.P. is your trusted partner. Contact us today to learn how we can help bring your vision to life with industry-leading silicone molding solutions.

2025 Trade Show Calendar

A.L.P. will be participating in many major lighting industry events in the coming months. Be sure to stop by to discuss your requirements and applications with our expert team!

IES25 | The Lighting Conference

August 21-23, 2025

Anaheim Marriott

Anaheim, California

IES Street & Area Lighting Conference

September 21-24, 2025

Hilton New Orleans Riverside

New Orleans, LA

LEDucation

April 14-15, 2026

New York Hilton Midtown

New York City, NY

Light + Building 2026

March 8-13, 2026

Frankfurt am Main

Press Release: A.L.P. Appoints Jeff Schirm as Southern Region Manager to Drive Growth in Custom Molding

[Niles, IL] — A.L.P. is pleased to announce the appointment of Jeff Schirm as Southern Region Manager, based out of the company’s ISO9001-certified manufacturing facility in Dickson, TN. Jeff brings over 20 years of experience in engineered plastics, with a strong background in working directly with some of the world’s largest manufacturers and their mechanical design engineering teams across the globe.

Throughout his career, Jeff has developed deep expertise in a wide range of base materials with precise specifications for form, fit, and function. He has actively supported 17 diverse markets that demand strict manufacturing standards and has managed both direct and independent sales representatives throughout North America. His experience also includes overseeing customer-driven capital equipment projects in manufacturing and distribution environments, handling complex requirements from system design to project management and implementation.

In his new role at A.L.P., Jeff will focus on generating and serving custom molding business, targeting markets outside of lighting, including automotive, medical, appliance and HVAC.

Located in the thriving Nashville Metropolitan area, Jeff is well-positioned to engage with some of the country’s fastest-growing companies. His extensive plastics industry knowledge and local market insight will play a pivotal role in expanding A.L.P.’s reach into these high-growth sectors.

“We are excited to welcome Jeff to the A.L.P. team,” said Tom Barnes, Vice President and Business Manager at A.L.P. “His expertise and leadership will be instrumental as we broaden our custom molding capabilities and strengthen our presence in new markets.”

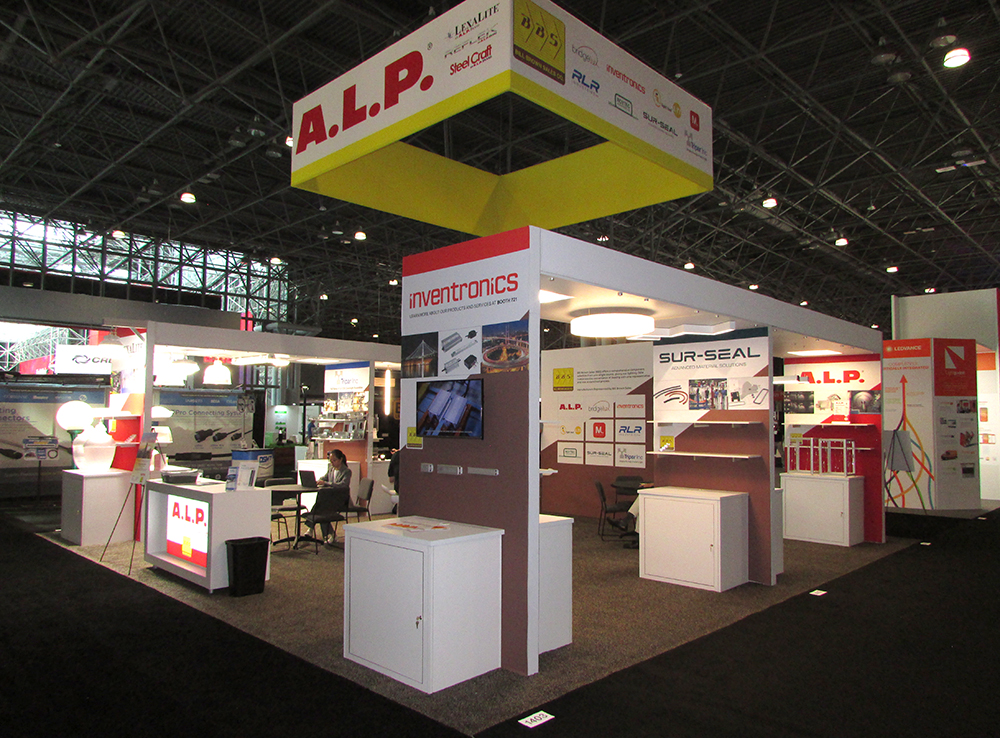

Meet A.L.P. at 2025’s Top Lighting Trade Shows!

See You at the Show!

A.L.P. is excited to showcase our extensive catalog of lighting components and custom manufacturing capabilities at several premier U.S. lighting industry trade shows in 2025.

We understand the importance of in-person interactions. Before investing in components for your fixture design, it’s essential to see them, test them, and ensure they meet your exact objectives. Similarly, when selecting a partner for custom-molded optical components or fabricated metal parts, sitting down with manufacturing experts is key to building trust and confidence.

With corporate travel budgets tighter than ever, making the most of your time and resources is critical. That’s why the A.L.P. team is committed to maximizing the value of your trade show visits. We’re bringing our best innovations and brightest experts to these industry-leading events:

LEDucation | March 18–19, 2025 | New York, NY

Lightfair International | May 4–8, 2025 | Las Vegas, NV

IES25—The Lighting Conference | August 21–23, 2025 | Anaheim, CA

IES Street and Area Lighting Conference | September 21–24, 2025 | New Orleans, LA

We’d love to connect with you at these shows! Visit our booth to explore our products, meet our team, and discover how we can support your projects. To ensure dedicated time with us, contact your regional sales manager to schedule a one-on-one appointment. If you’re planning to attend, let A.L.P. help make your trip worthwhile!

A.L.P. is a leading global supplier of lighting components, providing a diverse portfolio of products and services tailored to the needs of lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. delivers the industry’s most comprehensive range of optical components, LED fixture kits, custom services, and more. With over 40 years of experience, A.L.P. continues to set the standard for quality and innovation. The company’s premier brands, including LexaLite® and Steel Craft, are trusted worldwide for their performance and reliability.

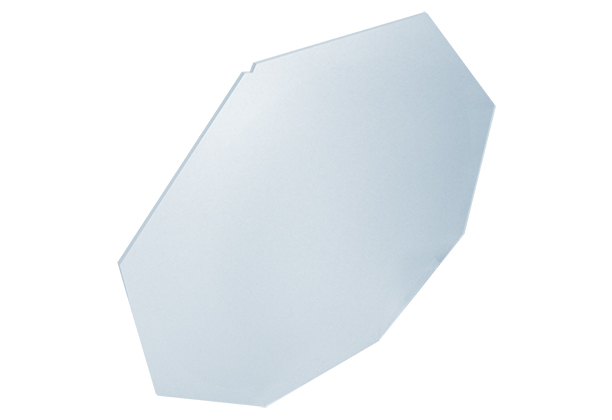

A.L.P. Introduces Octagonal Large Area Edgelit Panel for Commercial Fixtures

Niles, IL – A.L.P., a leader in innovative lighting solutions, announces a new commercial lighting optic, the Octagonal Large Area Edgelit Panel. This newly designed lens offers OEMs a combination of performance, efficiency, and versatility.

A.L.P.’s Octagonal Large Area Edgelit Panel is engineered for a variety of commercial applications, such as parking garages and similar settings. The panel’s wide beam angle produces uniform and glare-free illumination, ensuring optimal visibility and comfort. Featuring an octagonal shape with a centered round optic, the panel’s slim profile allows it to be used with rigid LED boards to facilitate alignment and heat sinking.

Injection molded from acrylic for durability and UV resistance, the octagonal panel offers reliability and performance for many commercial fixture designs. It also can be laser cut to smaller finished sizes on request.

“The Octagonal Large Area Edgelit Panel was designed with visual comfort in mind,” said Tom Barnes, Vice President and Business Manager. “We are pleased to offer a solution that prioritizes performance, efficiency, and design versatility for lighting OEMs.”