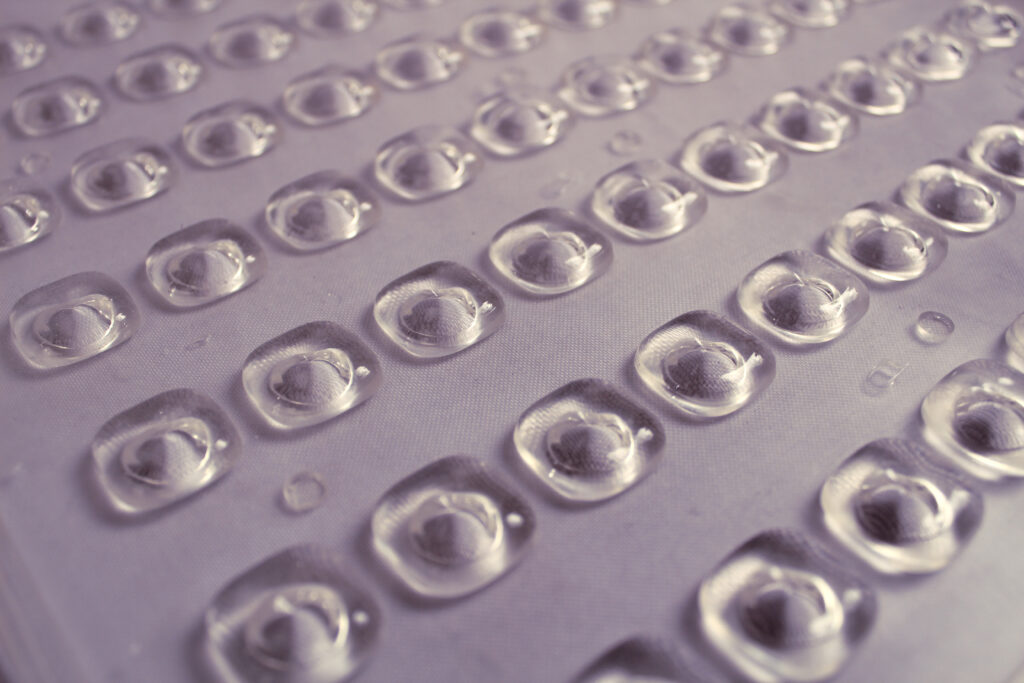

Why Silicone is Revolutionizing Optical Molding

In the world of precision optics, choosing the right material for your molding project can significantly impact performance, durability, and efficiency. Optical silicone molding is emerging as a game-changer, offering advantages that surpass traditional thermoplastics. A.L.P. provides industry-leading expertise in optical silicone molding, combining advanced equipment, tooling, and optical engineering to deliver high-quality solutions. Our in-house photometry lab enables real-time evaluation of first samples, ensuring optimized results from concept to production.

The Advantages of Optical Silicone Molding

When selecting materials for optical applications, Moldable Optical Silicone (MOS) stands out due to its unique properties. Here’s why optical silicone is revolutionizing the industry:

Superior Optical Clarity and Light Transmission

• Optical silicone provides greater than 91% light transmittance, ensuring maximum efficiency in lighting and optical applications.

• A refractive index of 1.41, it enables high-performance optical designs.

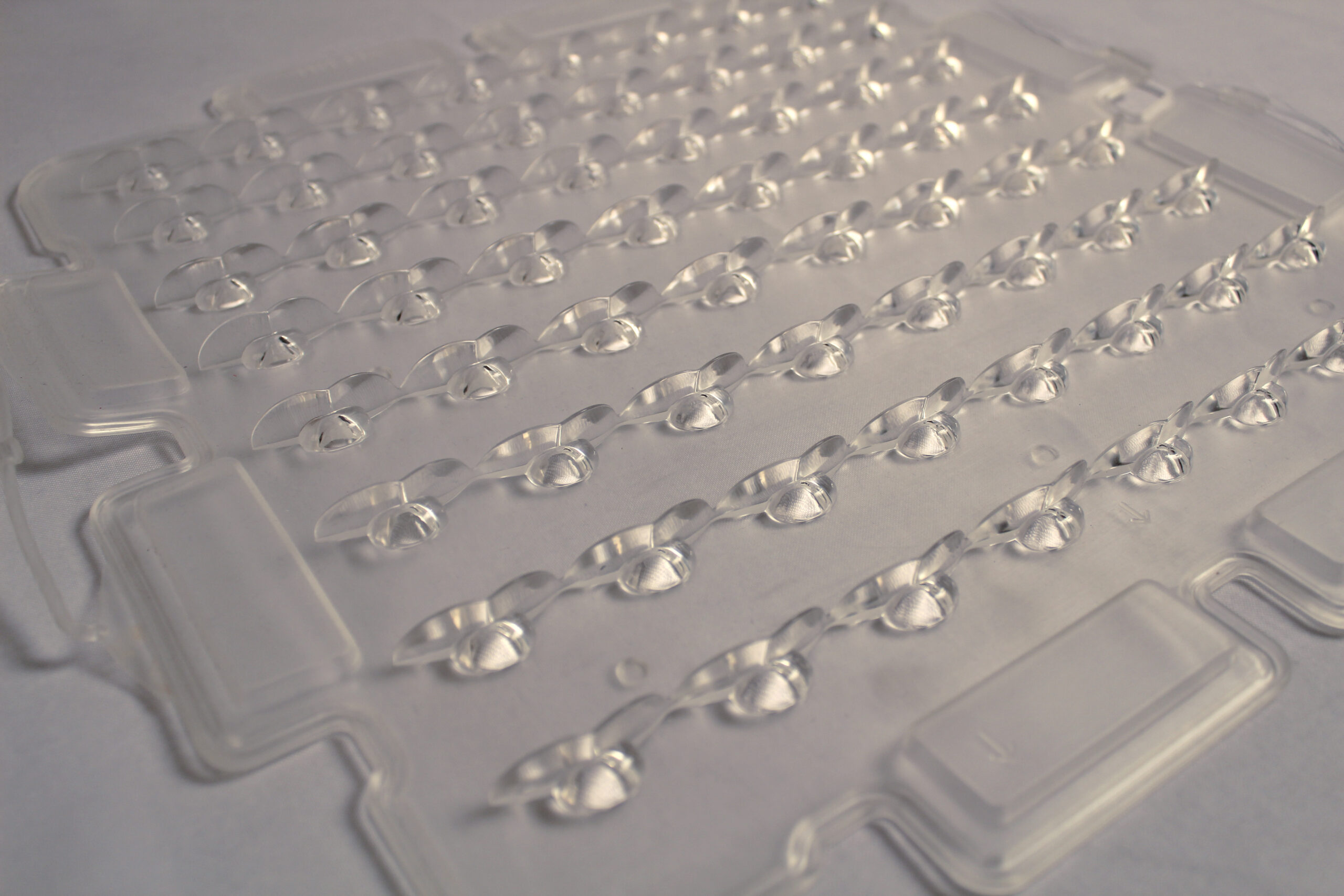

Exceptional Moldability and Precision

• Its low viscosity allows for excellent mold replication, capturing fine details with precision.

• Unlike thermoplastics, silicone requires low clamp tonnage, reducing production costs and complexity.

• Negative draft (undercut) features can be achieved with optical silicone, making it highly versatile for complex geometries.

Unmatched Durability and Environmental Resistance

• Silicone offers an exceptional continuous service temperature range from -45°C to +200°C, maintaining stability in extreme conditions.

• Most optical silicone grades are immune to UV degradation, ensuring long-lasting performance without yellowing or material breakdown.

• Exceptional impact resistance makes it ideal for rugged applications.

Versatility in Molding and Integration

• Insert molding capabilities with plastic, metal, and glass allow for integrated component manufacturing.

• Silicone expands when molded, allowing for thicker wall sections with no sink marks, a common issue with thermoplastics.

• Its ability to provide self-gasketing and self-mounting functionalities reduces the need for additional components and assembly steps.

Why Choose A.L.P. for Optical Silicone Molding?

A.L.P. stands at the forefront of optical silicone molding, leveraging cutting-edge equipment, innovative engineering, and a dedicated in-house photometry lab. Our expertise ensures:

• Rapid prototype development and testing

• Precision molding with complex geometries

• Reliable, high-performance optical solutions for demanding applications

If you’re considering optical silicone molding for your next project, A.L.P. is your trusted partner. Contact us today to learn how we can help bring your vision to life with industry-leading silicone molding solutions.

A.L.P., Enhanced LED Performance, Exceptional Moldability and Precision, high-performance optical solutions for demanding applications, immune to UV degradation, LED, LexaLite, Moldable Optical Silicone (MOS), Precision molding with complex geometries, precision optics, Rapid prototype development and testing, Reliable, Superior Optical Clarity and Light Transmission, Unmatched Durability and Environmental Resistance, Versatility in Molding and Integration

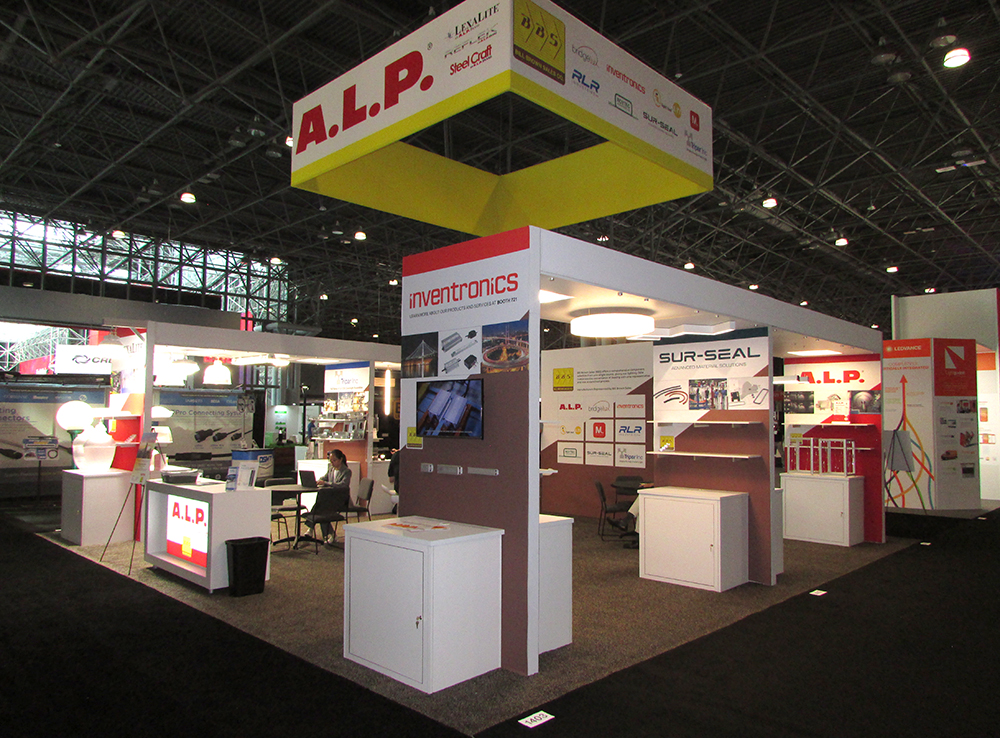

Meet A.L.P. at 2025’s Top Lighting Trade Shows!

See You at the Show!

A.L.P. is excited to showcase our extensive catalog of lighting components and custom manufacturing capabilities at several premier U.S. lighting industry trade shows in 2025.

We understand the importance of in-person interactions. Before investing in components for your fixture design, it’s essential to see them, test them, and ensure they meet your exact objectives. Similarly, when selecting a partner for custom-molded optical components or fabricated metal parts, sitting down with manufacturing experts is key to building trust and confidence.

With corporate travel budgets tighter than ever, making the most of your time and resources is critical. That’s why the A.L.P. team is committed to maximizing the value of your trade show visits. We’re bringing our best innovations and brightest experts to these industry-leading events:

LEDucation | March 18–19, 2025 | New York, NY

Lightfair International | May 4–8, 2025 | Las Vegas, NV

IES25—The Lighting Conference | August 21–23, 2025 | Anaheim, CA

IES Street and Area Lighting Conference | September 21–24, 2025 | New Orleans, LA

We’d love to connect with you at these shows! Visit our booth to explore our products, meet our team, and discover how we can support your projects. To ensure dedicated time with us, contact your regional sales manager to schedule a one-on-one appointment. If you’re planning to attend, let A.L.P. help make your trip worthwhile!

A.L.P. is a leading global supplier of lighting components, providing a diverse portfolio of products and services tailored to the needs of lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. delivers the industry’s most comprehensive range of optical components, LED fixture kits, custom services, and more. With over 40 years of experience, A.L.P. continues to set the standard for quality and innovation. The company’s premier brands, including LexaLite® and Steel Craft, are trusted worldwide for their performance and reliability.

A.L.P., aftermarket, Custom Manufacturing, IES Street and Area Lighting, IES25, LED Fixture Kits, LEDucation, LexaLite, Lightfair International, Lighting, Lighting Components, OEMs, Optical Components, SteelCraft

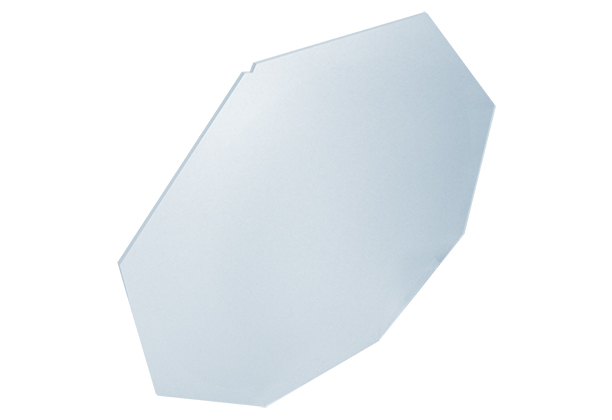

A.L.P. Introduces Octagonal Large Area Edgelit Panel for Commercial Fixtures

Niles, IL – A.L.P., a leader in innovative lighting solutions, announces a new commercial lighting optic, the Octagonal Large Area Edgelit Panel. This newly designed lens offers OEMs a combination of performance, efficiency, and versatility.

A.L.P.’s Octagonal Large Area Edgelit Panel is engineered for a variety of commercial applications, such as parking garages and similar settings. The panel’s wide beam angle produces uniform and glare-free illumination, ensuring optimal visibility and comfort. Featuring an octagonal shape with a centered round optic, the panel’s slim profile allows it to be used with rigid LED boards to facilitate alignment and heat sinking.

Injection molded from acrylic for durability and UV resistance, the octagonal panel offers reliability and performance for many commercial fixture designs. It also can be laser cut to smaller finished sizes on request.

“The Octagonal Large Area Edgelit Panel was designed with visual comfort in mind,” said Tom Barnes, Vice President and Business Manager. “We are pleased to offer a solution that prioritizes performance, efficiency, and design versatility for lighting OEMs.”

A.L.P., Injection Molded, LexaLite, Octagonal Large Area Edgelit Panel, Parking Garage, wide beam angle

A.L.P.’s Lindy® and Lineman™ Post-Top Optics Offered in Two Pieces

Simple solution saves time, freight, and cost

A.L.P. offers two of its Industry-leading post-top optics in two pieces to simplify installation and save you money.

Freight costs can be lowered dramatically, with refractor tops and caps nested and shipped separately, cutting the weight and size of bulkier shipments. Assembly is easy and can be done on-site without tools.

Lineman™ also is offered with optional caps and finials, allowing you to expand your product offering easily and inexpensively.

In addition to saving money, the Lindy® and Lineman post tops outperform other one-piece solutions for roadways, walkways, parks, and residential outdoor lighting. Their outstanding features and benefits include:

• Visually pleasing

• Compatible with HID or LED

• Lower glare

• Durable

• UV stable

• Impact resistant

• Material choices

• 8” or 9” necks

• Optional accessories

A.L.P., Acrylic, Clear Acrylic, Clear Polycarabonate, HID, injection molding, LED, LexaLite, Lindy, Lineman, Lumieo Acrylic, Post Top, refractor tops, residential outdoor lighting, UV Stable

New Post-Top Combinations to Expand Your Product Line

Fewer SKUs, Cheaper Freight, Lower Overall Cost

A.L.P.’s newest post-top lighting innovation allows our model 401 Lineman™ top and cap to be used with our industry-leading model 425 Lindy® bottom, so you can add to the variety of your traditional street and area lighting while cutting costs and keeping SKUs to a minimum.

The secret is in the design of Lineman’s injection molded top and cap. Using a snap-fit feature, it is attached in the field without tools. The top and bottom optics are shipped separately, dramatically reducing freight costs up to 70 percent versus pre-assembled post tops and eliminating the need—and cost—of attaching clamp bands.

This interchangeable option combines the look and performance of the Lindy with the value of the Lineman, adding variety to your product offering with the most economical, environmentally friendly approach. Other new options include new black acrylic tops for some Lineman and Lindy configurations.

All Lindy and Lineman acrylic post tops come with a 10-year warranty against discoloration. Why wait when you can add variety and lower costs with a classic post-top aesthetic and superior performance?

A.L.P., Black Acrylic, injection molding, Interchangeable, LexaLite, Lindy 425, Lineman 401, Lumieo, Polycarbonate, Post Top, Post-Top Combinations, Post-Top Configurator, Snap-fit, Street and Area Lighting

Press Release: A.L.P. Announces Leadership Changes, Promotions

(Niles, IL) A.L.P., leading global supplier of components for lighting and other manufacturing industries, is pleased to announce leadership changes to strengthen the company and its customer relationships. Effective July 2, 2023, Adam Mayse has been promoted to President and Chief Operating Officer, from Metals Business Unit Manager. In addition, Tom Barnes has been promoted to VP And Business Manager, from Optical Business Unit Manager. These moves are part of a larger strategic reorganization to centralize product-related activities, streamline operations, and support the changing requirements of the marketplace.

In his new role as President and COO, Adam Mayse will have strategic and managerial responsibility for manufacturing operations, customer experience, corporate services, finance, sales, and marketing. Adam joined A.L.P. in 1997 and has held a variety of management positions in engineering, operations, and product management, as well as domestic and international sales. He has also worked in other technical industries outside of lighting and brings a fresh perspective to delivering value to A.L.P.’s OEM partners and customers.

As VP and Business Manager, Tom Barnes will have enterprise-wide responsibility for A.L.P.’s product development, marketing communications, design engineering, sales resource, and pricing functions. Tom has managed the company’s optical business unit since 2007 when A.L.P. acquired Spectrus, Inc., including the LexaLite® brand. He is a Certified Lighting Professional and holds four patents related to plastics in lighting.

“We congratulate Adam and Tom on their new positions,” said Steve Brown, A.L.P.’s CEO. “They have extensive knowledge of the lighting industry and enduring relationships with our customers. They are uniquely qualified to succeed in their expanded roles, and to move our customer-focused strategy forward.”

After the transition, Steve Brown will remain as CEO and David Brown, former COO, will be stepping away from day-to-day involvement after 46 years of service to the company. David will be an active member of A.L.P.’s Board of Directors, using his extensive experience to support budgeting, major projects, and strategic planning initiatives.

A.L.P., Adam Mayse, LexaLite, President and Chief Operating Officer, Promotions, Steve Brown, Tom Barnes, VP and Business Manager