Press Release: A.L.P. Appoints Jeff Schirm as Southern Region Manager to Drive Growth in Custom Molding

[Niles, IL] — A.L.P. is pleased to announce the appointment of Jeff Schirm as Southern Region Manager, based out of the company’s ISO9001-certified manufacturing facility in Dickson, TN. Jeff brings over 20 years of experience in engineered plastics, with a strong background in working directly with some of the world’s largest manufacturers and their mechanical design engineering teams across the globe.

Throughout his career, Jeff has developed deep expertise in a wide range of base materials with precise specifications for form, fit, and function. He has actively supported 17 diverse markets that demand strict manufacturing standards and has managed both direct and independent sales representatives throughout North America. His experience also includes overseeing customer-driven capital equipment projects in manufacturing and distribution environments, handling complex requirements from system design to project management and implementation.

In his new role at A.L.P., Jeff will focus on generating and serving custom molding business, targeting markets outside of lighting, including automotive, medical, appliance and HVAC.

Located in the thriving Nashville Metropolitan area, Jeff is well-positioned to engage with some of the country’s fastest-growing companies. His extensive plastics industry knowledge and local market insight will play a pivotal role in expanding A.L.P.’s reach into these high-growth sectors.

“We are excited to welcome Jeff to the A.L.P. team,” said Tom Barnes, Vice President and Business Manager at A.L.P. “His expertise and leadership will be instrumental as we broaden our custom molding capabilities and strengthen our presence in new markets.”

A.L.P., Appliance, Automotive, Custom Molding, Dickson, engineered plastics, HVAC, ISO9001 Certified, Jeff Schirm, Medical, Southern Region Manager

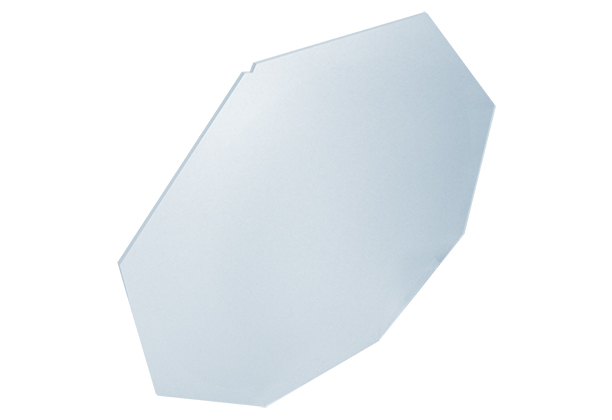

A.L.P. Introduces Octagonal Large Area Edgelit Panel for Commercial Fixtures

Niles, IL – A.L.P., a leader in innovative lighting solutions, announces a new commercial lighting optic, the Octagonal Large Area Edgelit Panel. This newly designed lens offers OEMs a combination of performance, efficiency, and versatility.

A.L.P.’s Octagonal Large Area Edgelit Panel is engineered for a variety of commercial applications, such as parking garages and similar settings. The panel’s wide beam angle produces uniform and glare-free illumination, ensuring optimal visibility and comfort. Featuring an octagonal shape with a centered round optic, the panel’s slim profile allows it to be used with rigid LED boards to facilitate alignment and heat sinking.

Injection molded from acrylic for durability and UV resistance, the octagonal panel offers reliability and performance for many commercial fixture designs. It also can be laser cut to smaller finished sizes on request.

“The Octagonal Large Area Edgelit Panel was designed with visual comfort in mind,” said Tom Barnes, Vice President and Business Manager. “We are pleased to offer a solution that prioritizes performance, efficiency, and design versatility for lighting OEMs.”

A.L.P., Injection Molded, LexaLite, Octagonal Large Area Edgelit Panel, Parking Garage, wide beam angle

Press Release: William “Bill” Brown Passes Away

at 95

(Niles, IL). Bill Brown, founder and chairman of Bill Brown Sales and A.L.P., passed away peacefully yesterday, surrounded by family, in Glenview, IL. He was 95 years old.

Bill and his wife Norma started the Bill Brown Sales component sales agency in 1955 from the kitchen table of their apartment while raising their young family. Bill felt pressure to expand services as the business grew, so he entered the manufacturing industry, founding A.L.P. in 1972. Over the course of his almost 70-year career, he witnessed and responded to a technological revolution in lighting, moving from traditional light sources to LEDs. Bill created growth opportunities by listening, learning, and finding new ways to meet customer needs.

Bill’s entrepreneurial talent and engaging personality made him a central figure in the lighting community, and his enduring relationships will remain his legacy. He was a prolific correspondent who sent out hundreds of follow-ups weekly, first by US mail and then by email. Over the years, he received numerous industry awards and accolades, including the first-ever Edison Report Lifetime Achievement Award, the IES Louis B Marks Award, and a Lifetime Achievement Award from RSM McGladrey. He gave back to others in many ways, supporting his local synagogue, Temple Jeremiah, and the cancer research of the City of Hope, among many charitable organizations.

Despite its growth, the organization remains a family business at its core, with Bill’s son Steve serving as CEO and his recently retired son David sitting on A.L.P.’s Board of Directors. Grandson Michael is a Regional Sales Manager for BBS, while grandson Scott serves as a Process Analyst. The values Bill Brown instilled, including mutual respect, philanthropy, and good old-fashioned hard work, will remain as the company’s guiding principles, honoring his memory for years to come.

A.L.P., Bill Brown, Bill Brown Sales, Chairman, Founder, William "Bill" Brown, William Brown

A.L.P. Announces New Hires

We are pleased to announce two new additions to the A.L.P. team:

Abelardo Martinez was recently hired as Regional Sales Manager, focusing on non-lighting customers in Mexico. He will be responsible for developing and growing custom manufacturing business with OEMs from automotive, appliance, heavy equipment, medical, and other industries. Abelardo has an extensive business development background and is experienced in interfacing with engineering and manufacturing teams.

Pablo Villarreal, our new Metals Product Manager, is working from A.L.P.’s Monterrey facility. He is responsible for the Metals product portfolio, including pricing and technical support for the sales and customer service teams. Pablo has a strong background in metals processing and sales. He will train in Monterrey for the next few months and travel with our regional sales managers.

A.L.P., Metal Product Manager, Mexico, Monterrey, New Hire, Non-Lighting, Pricing, Technical Support

Press Release: A.L.P. Announces Leadership Changes, Promotions

(Niles, IL) A.L.P., leading global supplier of components for lighting and other manufacturing industries, is pleased to announce leadership changes to strengthen the company and its customer relationships. Effective July 2, 2023, Adam Mayse has been promoted to President and Chief Operating Officer, from Metals Business Unit Manager. In addition, Tom Barnes has been promoted to VP And Business Manager, from Optical Business Unit Manager. These moves are part of a larger strategic reorganization to centralize product-related activities, streamline operations, and support the changing requirements of the marketplace.

In his new role as President and COO, Adam Mayse will have strategic and managerial responsibility for manufacturing operations, customer experience, corporate services, finance, sales, and marketing. Adam joined A.L.P. in 1997 and has held a variety of management positions in engineering, operations, and product management, as well as domestic and international sales. He has also worked in other technical industries outside of lighting and brings a fresh perspective to delivering value to A.L.P.’s OEM partners and customers.

As VP and Business Manager, Tom Barnes will have enterprise-wide responsibility for A.L.P.’s product development, marketing communications, design engineering, sales resource, and pricing functions. Tom has managed the company’s optical business unit since 2007 when A.L.P. acquired Spectrus, Inc., including the LexaLite® brand. He is a Certified Lighting Professional and holds four patents related to plastics in lighting.

“We congratulate Adam and Tom on their new positions,” said Steve Brown, A.L.P.’s CEO. “They have extensive knowledge of the lighting industry and enduring relationships with our customers. They are uniquely qualified to succeed in their expanded roles, and to move our customer-focused strategy forward.”

After the transition, Steve Brown will remain as CEO and David Brown, former COO, will be stepping away from day-to-day involvement after 46 years of service to the company. David will be an active member of A.L.P.’s Board of Directors, using his extensive experience to support budgeting, major projects, and strategic planning initiatives.

A.L.P., Adam Mayse, LexaLite, President and Chief Operating Officer, Promotions, Steve Brown, Tom Barnes, VP and Business Manager

Press Release: A.L.P.® Joins RLR Industries to Launch a Troffer Luminaire Component Kit Line

(Niles, IL) A.L.P. has teamed up with RLR Industries to introduce a family of four troffer component kits that can help lighting OEMs to quickly drive incremental revenue without devoting resources and time needed to develop their own line. The ELFT kits leverage architectural troffer diffusers from RLR with A.L.P.’s proven, durable EL housings and door frames. Offered in standard 2’x2’ and 2’ x 4’ sizes, they also feature a new externally mounted driver compartment, resulting in an uncluttered fixture housing cavity that improves performance, versatility, and contributes to the shadow-free illumination of the thermoformed diffuser.

The uniformly luminous, evenly diffused component sets produce a specification grade troffer with visual sculpture and depth. The diffusers are offered in four design themes that emulate popular architectural design trends, so the troffers are suitable for applications across a variety of commercial spaces.

The unique conditions in today’s lighting market present challenges for lighting OEMs. “These component kits will allow our customers a hassle-free opportunity to introduce new fixtures,” explains Adam Mayse, A.L.P.’s Metals Business Unit Manager. “All they need to do is add electronics using either Standard or Emitter LED boards, and they are good to go,” he adds.

“As a manufacturer of engineered plastics solutions for nearly 70 years, our goal remains to produce components that combine attractive designs and innovative materials,” states Stewart Lewis, Vice President at RLR Industries. “This design partnership with A.L.P. broadens the availability and opportunity to feature RLR’s proprietary plastics in more fixtures and settings,” Lewis says.

A.L.P., Diffuser, EL Housing, ELFT, ELFT10, ELFT13, ELFT15, ELFT3, recessed, RLR, RLR Industries, troffer, troffer component kits