Why you should care…about glare!

The importance of reflectors on LED highbays.

Do you ever wear a baseball cap or sunglasses? Ever use your car visor? These shielding actions reduce glare, or “bad” light that detracts from our ability to see. In a factory, warehouse, or retail facility, highbays are installed to light the space, but if the highbays are unshielded, glare interferes with what we can see. In commercial settings, glare is more than an inconvenience. This low visibility can hurt safety, productivity, and health.

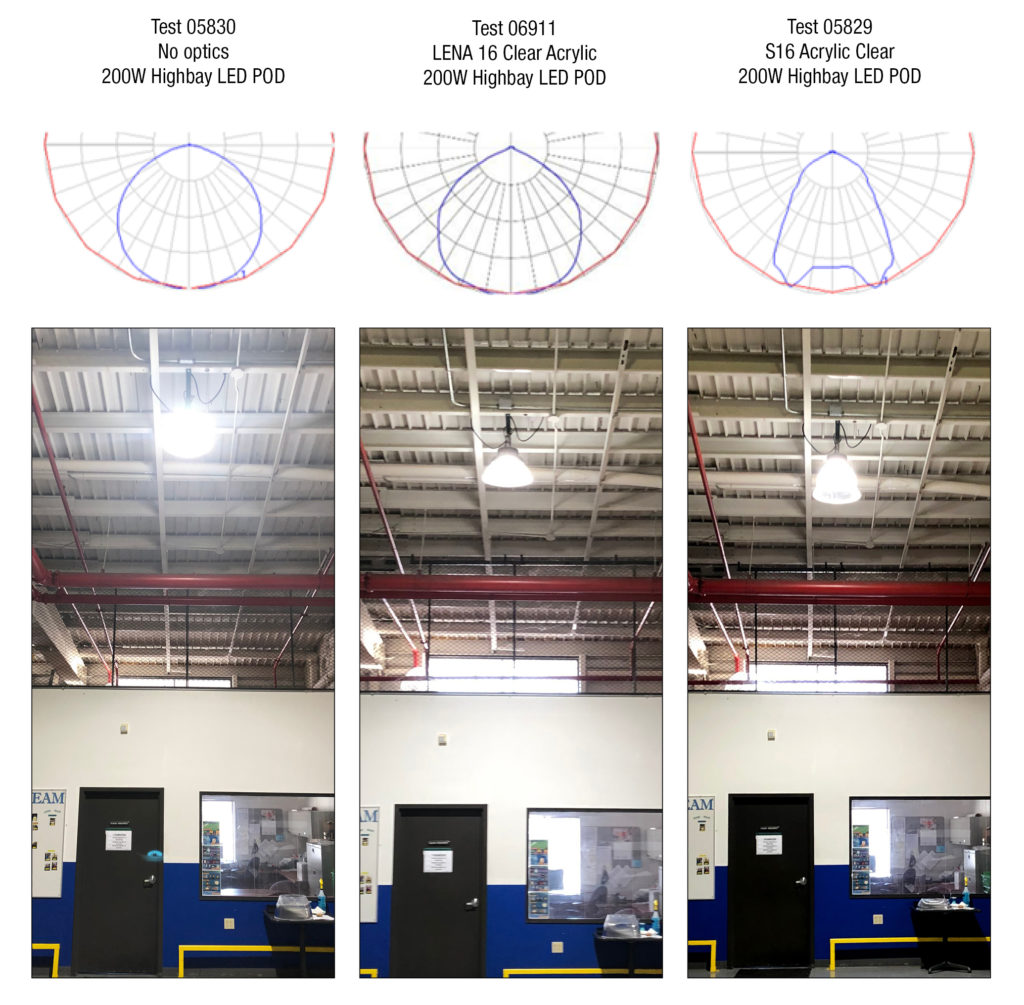

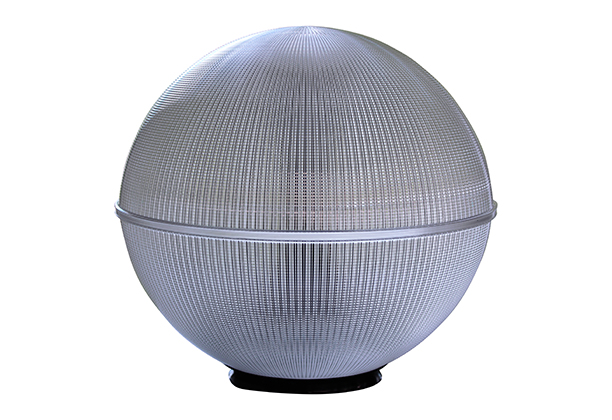

Below are three photometry tests on the same highbay. The first with no reflector, the second with a shallow reflector, and the third with a deeper reflector. The glare reduction, while having little impact on lumen output, is dramatic.

Using a reflector, not only are high angle candela reduced, but they are also emitted over a much larger surface area, reducing high angle luminance by a hundredfold! If your facility has light-colored ceilings, installing reflectors has the added benefit of producing uplight. Uplight further reduces apparent brightness, eliminates the “cave” effect, and makes the space feel larger.

LexaLite® brand glare shields, from the economical and shallow LENA 16™ to the deep, high-performance S16, kill the glare without killing the light. Specify the LENA 16 or S16 by LexaLite on your next highbay project. We can customize the mounting mechanism to fit virtually any highbay.

Meet the Team: Kurt Puffpaff

Kurt Puffpaff ROCKS! Though in Kurt’s case, we mean that quite literally. A musician and music aficionado, Kurt plays guitar, sings, and is a huge fan of ‘70s rock bands like AC/DC, Styx and Led Zeppelin. He also writes and records his own original tunes, played on his favorite Birdseye Maple Les Paul guitar. Besides his love for music, Kurt is an avid outdoorsman and a die-hard Kansas City Chiefs fan.

Born and raised in Charlevoix, Michigan, Kurt has moved around the Midwest for his career before returning to his hometown a few years ago and settling with his wife Diane and their four sons, aged from 11 to 22.

Kurt is currently the National Sales Manager for A.L.P.’s custom optical products, but he has been in the lighting industry since 1993. He started his career as a territory manager for LexaLite (now part of A.L.P.) where he learned the business from the ground up, even delivering a few orders by truck when the business depended on it. Drawing on his decades of expertise in injection molding, Kurt can answer almost any molding question that comes his way. You are also invited to pick his brain on classic rock, football, or hunting.

Meet the Team: Alan Dorsky

At one of Alan Dorsky’s first sales meetings with A.L.P., he was kind enough to include a pronunciation guide to help attendees decipher his extremely strong, distinctive Boston accent. Fortunately for our customers, phrases like “Pahk the cah in Hah-vahd yahd,” rarely come up during lighting sales calls!

Alan’s lighting career spans over four decades, as he’s held sales and sales management positions with a number of lighting companies including Nutone Manufacturing, Sterling Lighting and Lightcraft of California. With that much time in the industry, Alan has numerous sales “war stories.” He will certainly never forget, for example, visiting customers in the Midwest and having to drive through a solid three hours of tornadoes to get to his destination!

Alan joined A.L.P. when we purchased his family’s company, Reflek Manufacturing. He spent 19 years as Reflek’s VP of marketing and sales and has been instrumental in the continued success of this custom line of spun aluminum reflectors. Alan also heads sales for A.L.P.’s global sourcing solutions program.

He and his wife Nancy live in Scituate, Massachusetts. They are parents to sons Adam and Jason, and proud grandparents of Miles, Jameson, Evan and Justin. As Alan and his fellow Bostonians would say, his family is “wicked good!”

Meet the Team: Steve Dix

During the workweek, Steve Dix may focus on shipping products to our customers, but on summer weekends, he is focused on a different kind of shipping, at the helm of his Ocean Yacht Sport Fishing boat. When not sailing the Chesapeake Bay and North Atlantic, he enjoys traveling the globe with his wife Patty, a retired music professor, and their grown children Brian, Kaitlyn, and Sean. Together, they have visited Africa, England, France, Ireland, Italy, the Netherlands, Norway, and Turks & Cacaos.

When it comes to extensive travel, he may have seen it all. But with more than 25 years of manufacturing experience in a variety of roles with A.L.P., Steve has seen (and done) it all where the lighting industry is concerned, too.

Since joining A.L.P., Steve has held progressively responsible management positions in the areas of warehousing, operations, and logistics. He currently serves as Vice President, Customer Fulfillment, managing the entire order processing experience from customer service and inventory to warehousing and logistics.

Meet the Team: Tom Barnes

Do you know the difference between a jib and a spinnaker? Or where to locate Port and Starboard? You can turn to A.L.P.’s sailing expert, Tom Barnes, for the answer to these puzzling questions and more. When he is not working as Vice President and Business Manager for A.L.P.’s LexaLite® brand, you can find Tom competing in (and often winning) races with the Charlevoix Yacht Club. In addition to sailing, Tom and his wife, Pam, enjoy all that scenic Northern Michigan offers, from golf to hiking and skiing. They are the proud parents of two daughters, Lexie and Abbey.

Tom’s other passion? Plastics! He studied plastics engineering at Ferris State University before joining LexaLite, the company founded by his father, Josh Barnes. Over the years, he held positions in sales, management, operations, and strategic development before joining A.L.P. when LexaLite was acquired in 2007.

In his current role with A.L.P., he is responsible for defining and promoting the plastic optical product line, ensuring profitability by managing product development, production, pricing, and related functions.

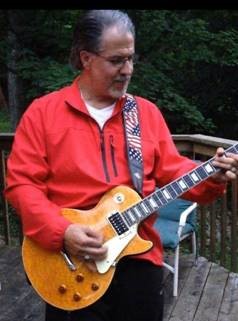

Press Release: A.L.P. Introduces the Rayder™, a Modern, High-Performance Prismatic Post-Top Sphere

(Niles, IL) -A.L.P. Lighting Components, a leading global manufacturer of lighting components and kits, has added the Rayder™ post-top prismatic sphere to its 400 Series injection molded optics for outdoor lighting. The Rayder is designed to deliver a uniform distribution, higher efficiency, improved CRI, outstanding glare control, and a timeless appearance.

Today’s new post-top installations and retrofits need to be energy efficient, aesthetically pleasing, and provide safe illumination of walkways and streets. The Rayder excels in applications where brightness control is a priority. The Rayder’s optics reduce high angle glare and hide LED light sources while delivering a uniform glowing appearance. The Rayder also offers a significant improvement in efficiency when compared to diffuse or translucent blow molded spheres.

Suitable for 10′ – 20′ poles, the assembled spheres are 19.2″ in diameter, and are available with either 8″ diameter neck or other custom bottom openings. The Rayder is offered in Clear Optical Acrylic, Diffuse Acrylic, and Clear Polycarbonate. The top and bottom halves are easily attached using the affixed UV stable high bond double-sided adhesive ribbon for fast assembly and mounting. Acrylic versions are covered by a ten-year limited warranty.

“Optical glare control and the delivery of IES distributions are paramount features of A.L.P. LexaLite’s post top and dusk-to-dawn refractors,” says Kurt Puffpaff, National Sales Manager for Proprietary Products. “Utilizing A.L.P.’s existing optical prescriptions will increase efficiency, reduce glare and deliver light where light is needed,” he states. “Many fixtures incorporate white or diffuse lenses or no lenses at all. Applying A.L.P.’s optical component will improve fixture performance and application effectiveness,” Puffpaff concludes.

A.L.P. is a leading global supplier of lighting components, offering a diverse line of products and services for lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. offers the industry’s most comprehensive line of LED fixture kits, vapor-proof enclosures, unwired fixture bodies, louvers, and reflectors. A.L.P. Brands include Steel Craft, LexaLite®, and Reflek®