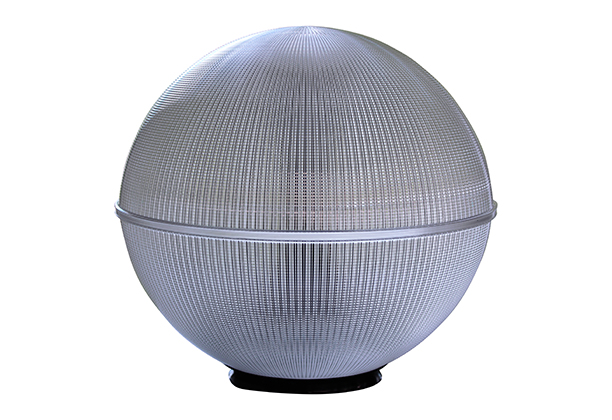

Press Release: A.L.P. Introduces the Rayder™, a Modern, High-Performance Prismatic Post-Top Sphere

(Niles, IL) -A.L.P. Lighting Components, a leading global manufacturer of lighting components and kits, has added the Rayder™ post-top prismatic sphere to its 400 Series injection molded optics for outdoor lighting. The Rayder is designed to deliver a uniform distribution, higher efficiency, improved CRI, outstanding glare control, and a timeless appearance.

Today’s new post-top installations and retrofits need to be energy efficient, aesthetically pleasing, and provide safe illumination of walkways and streets. The Rayder excels in applications where brightness control is a priority. The Rayder’s optics reduce high angle glare and hide LED light sources while delivering a uniform glowing appearance. The Rayder also offers a significant improvement in efficiency when compared to diffuse or translucent blow molded spheres.

Suitable for 10′ – 20′ poles, the assembled spheres are 19.2″ in diameter, and are available with either 8″ diameter neck or other custom bottom openings. The Rayder is offered in Clear Optical Acrylic, Diffuse Acrylic, and Clear Polycarbonate. The top and bottom halves are easily attached using the affixed UV stable high bond double-sided adhesive ribbon for fast assembly and mounting. Acrylic versions are covered by a ten-year limited warranty.

“Optical glare control and the delivery of IES distributions are paramount features of A.L.P. LexaLite’s post top and dusk-to-dawn refractors,” says Kurt Puffpaff, National Sales Manager for Proprietary Products. “Utilizing A.L.P.’s existing optical prescriptions will increase efficiency, reduce glare and deliver light where light is needed,” he states. “Many fixtures incorporate white or diffuse lenses or no lenses at all. Applying A.L.P.’s optical component will improve fixture performance and application effectiveness,” Puffpaff concludes.

A.L.P. is a leading global supplier of lighting components, offering a diverse line of products and services for lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. offers the industry’s most comprehensive line of LED fixture kits, vapor-proof enclosures, unwired fixture bodies, louvers, and reflectors. A.L.P. Brands include Steel Craft, LexaLite®, and Reflek®

400 Series, A.L.P., Glare Control, High-performance, Injection Molded, LexaLite, Outdoor Lighting, Post-top, Prismatic, Rayder, Sphere, uniform distribution

Little Lindy®, A Better Post Top at a Great Price

Dingy yellow with no optical control.

Crystal clear with optical control and an elegant, updated look.

Value Pricing. A.L.P. LexaLite® has leveraged manufacturing and sourcing efficiencies to drive costs out of our production process—and we are passing along the savings to you! Slash costs even more by purchasing our one-piece version that does not require buying clamp bands, costly on-site assembly, or expensive ongoing maintenance. Better Aesthetic. We have kept the traditional, turn-of-the-century look for a scenic post-top ambiance, as well as the cutting-edge photometric performance. The Little Lindy® is available with a distinctive, optical design and is offered in UV stabilized acrylic. It resists ugly yellowing and has a longer service life than blow-molded alternatives*. Superior Performance. Today’s Little Lindy features the same unsurpassed optical design. It is offered in Type III and Type V distributions. *Consult A.L.P. LexaLite® for UV tolerance, recommended operating temperatures, and service life of Clear Polycarbonate material. |

Read more about Little Lindy’s performance, aesthetics, and pricing.

better aesthetic, Clear Acrylic, Clear Polycarabonate, LexaLite, Little Lindy, Lumieo Acrylic, Reflector, Reflexor, superior performance, Type III, Type V, UV stabilized, value pricing

Press Release: A.L.P. Produces PPE Face Shields for COVID-19 Health Care Workers

Joining the fight against the COVID-19 pandemic, the injection molding team at A.L.P. LexaLite’s Charlevoix, MI facility mobilized to design and manufacture Personal Protective Equipment (PPE) face shields for front-line health care workers. They rapidly reorganized tooling and manufacturing functions to support this critical need, and they expect to have the first production models coming off the presses within days.

The company was initially approached by Charlevoix Hospital, looking for PPE. While primarily a manufacturer supplying components for lighting fixtures, A.L.P. has several customers in the health care sector. The team drew on its knowledge of health care requirements and standards to quickly design and tool the face shields in an unprecedented 10-day turnaround.

When in full production, A.L.P. can produce approximately 1400 face shields per day, and they plan to sell them at cost. “We will make them as long as they are needed,” states Steve Brown, CEO.

“This is one scenario I didn’t see coming,” Brown adds. “The COVID-19 crisis is tragic, yet it shows us what we can accomplish together when needed,” he observes. A.L.P. is not alone, as manufacturers all over the country are making similar efforts.

The A.L.P. face shield has some unique features. The plastic shield snaps onto a headband, and the shield is disposable. So, the caregiver can use the same headband throughout the day and simply snap on a new shield for each patient.

A.L.P. continues to operate during this crisis as an Essential Business, supplying into vital infrastructure such as construction, health care, transit, and government. The company has adjusted its practices, with the health and safety of employees, families, and communities as a top priority. The A.L.P. staff is working remotely when possible. All manufacturing locations have implemented additional measures to ensure safe distancing of employees, such as adjusting schedules, spacing equipment, and reorganizing meeting and break room spaces.

Charlevoix, COVID-19, disposable shield, Essential Business, headband, Health Care Workers, injection molding, LexaLite, Personal Protective Equipment, PPE Face Shields, tooling

Announcing the Next Generation of A.L.P.’s Lindy Family Post-Top Refractors

- Better Value

- Improved Aesthetics

- Same Unsurpassed Optical Performance

- No assembly required

A.L.P.’s The Lindy® 424 and Little Lindy® 408 Post Top are now available in one-piece versions, for better looks, reduced cost and faster installation—with no need for a metal clamp band!

In this new evolution, we have kept the traditional, turn-of-the-century look for a scenic post-top ambiance, as well as the cutting-edge photometric performance. The refractor bottom and top are glued, eliminating the need for other unsightly attachment methods and sealing the assembly for lower maintenance.

- No clamp band for lower cost

- One-piece design so no added fabrication

- No field assembly for faster installation

- Sealed for lower maintenance

For The Lindy, our larger product, the assembled refractor bottom and top are 15.9” in diameter, 23.16” high and are available with 8” or 9” diameter fitters.

When assembled, our smaller version, The Little Lindy, is 14.11” in diameter, 19.05” high, and available with an 8” fitter.

Like our standard models, the one-piece versions come in UV Stabilized Acrylic in Clear, Lumieo®, and also clear Polycarbonate.

424 Lindy, Acrylic, LexaLite, Lumieo, One-Piece, Post Top, refractors, The Lindy, Type III, Type V

Press Release: A.L.P. Introduces LENA 16™, a Cost-Effective, High Performing, Low Profile Reflector

(Niles, IL) -A.L.P. Lighting Components, a leading global manufacturer of lighting components and kits, has added the LENA 16™ shallow prismatic reflector to the “S Series” of optics. Designed for low-, mid- and high-bay LED fixtures, it offers superior glare control and an elegant aesthetic, combined with the versatility to accommodate a variety of light sources without expensive modifications.

The LENA 16 has a shallow design, optimizing cost without sacrificing high angle brightness control. The 10.36” flat top allows it to be easily adapted and directly attached to many fixtures. The lower flange works with a wide range of bottom lenses and standard clamp bands. The top can be cut to order with an opening of up to 10.66 inches.

Like their HID predecessors, today’s LED low-, mid- and high-bay fixtures should always be installed with optical or refractive control. Without this control, they emit high angle glare, causing a reduction in contrast and negatively affecting color and focus. By reducing high angle glare, LENA 16 improves visual comfort, provides even illumination, and can also increase worker efficiency in some settings. It is suitable for warehouse, industrial, commercial, and retail applications.

LENA 16 is available in Clear Acrylic, Clear Polycarbonate, Interface Acrylic, and Lumieo® Acrylic. It works with a wide range of LexaLite® brand bottom lenses.

A.L.P. is a leading global supplier of lighting components, offering a diverse line of products and services for lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. offers the industry’s most comprehensive line of LED fixture kits, vapor-proof enclosures, unwired fixture bodies, louvers and reflectors. A.L.P. Brands include Steel Craft, LexaLite®, and Reflek®

Clear Acrylic, Clear Polycarabonate, High Bay, Interface Acrylic, LED, LENA 16, LexaLite, Low Bay, Lumieo Acrylic, Mid Bay, Reflector, Reflexor, Shallow

Press Release: A.L.P. LexaLite® Adds New 240-Ton Silicone Press

A.L.P. Lighting Components, a leading global manufacturer of lighting components and kits, has added to its capacity with a new 240-ton injection molding press. This new equipment augments A.L.P.’s existing capacity of 180-, 240- and 660-ton presses, all of which run Moldable Optical Silicone (MOS). The new press features a shot size up to 9 ounces, mold bases up to 24” x 24” ,and can produce parts up to 20” x 20”.

Optical silicone has valuable properties for lighting, automotive, and other demanding applications. Optical silicone parts are impact and heat resistant while being less susceptible to degradation from UV. Silicone also is known for its refraction, reflection, and diffusion properties, along with self-mounting and self-gasketing features.

A.L.P. has replenished its silicone resin inventory, recovering from recent supply chain issues felt throughout the injection molding industry. “We struggled with the same shortages that everyone else did,” explains Tim DeYoung, A.L.P. LexaLite’s Director of Operations. “Fortunately, we now have a good inventory of raw material, and we are ready to take on new business,” he adds.

A.L.P. has a long history as a premier supplier of custom injection molded components for lighting, automotive, medical, marine, point-of-purchase, and other industries. A.L.P.’s expert team can collaborate on product design engineering, tool design and maintenance, innovative fast-track tooling, as well as offer materials expertise, production efficiencies, and distribution options. A variety of secondary operations and finishing services also are available, including UV coating, metalizing, laser cutting, and assembly. In addition to custom molding, A.L.P.’s LexaLite brand offers a comprehensive catalog of proprietary indoor and outdoor optical reflectors, as well as numerous high-performance LED fixture kits.

A.L.P. is an international leader in the design, manufacturing, and distribution of lighting components and components for other technical industries. We offer the industry’s most comprehensive line of products for OEMs and the aftermarket. For custom projects, our unique “360° Solutions” suite of custom services enables us to collaborate with customers at every stage of a product’s life cycle. Our core commitment is to provide superior service and product performance to every customer.

240-Ton, 240-Ton Silicone Press, injection molding press, LexaLite, Silicone, Silicone Molding