7 Things to Know Before You Choose Suspension Hardware

When designing a fixture, it’s easy to focus on performance or looks—but suspension is just as critical. The right suspension ensures safety, simplifies installation, and enhances overall design.

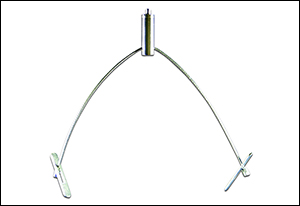

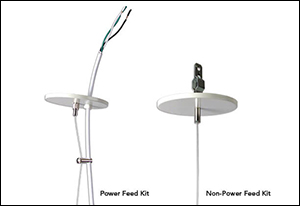

A.L.P. offers a complete portfolio of suspension solutions, including Single-Point, V Hook, Universal Yoke and Toggle, canopy kits, and custom-length tethers. But how do you choose the best option for your project?

Here are seven vital considerations:

- Safety First – Load capacity, strength, and certifications

- Aesthetic Fit – How suspension complements design appearance

- Ease of Installation – Saving time for contractors

- Flexibility & Adjust ability – Accommodating various ceiling heights and fixture weights

- Compatibility – Options including Single-Point, V Hook, Yoke/Toggle, canopy kits, and custom lengths

- Compliance – Meeting UL/ETL requirements and regional standards

- Customization – Tailored solutions with custom tethers and kits

Interested in stronger, safer, smarter fixture suspension?

Canopy Kits, Compliance, Safety, Single-Point, Suspension Hardware, Suspension kits, Suspension Solutions, Suspension Systems, Tethers, Universal Yoke and Toggle, V Hook

Key Considerations When Choosing a Silicone Molder

Optimizing Optical Silicone Molding for Performance and Efficiency

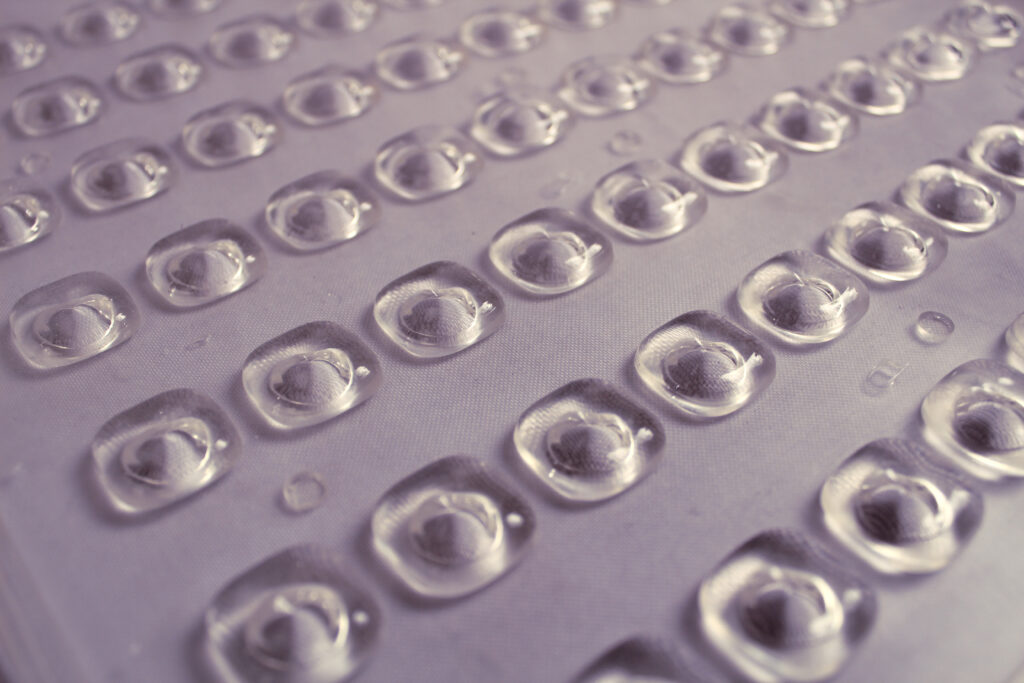

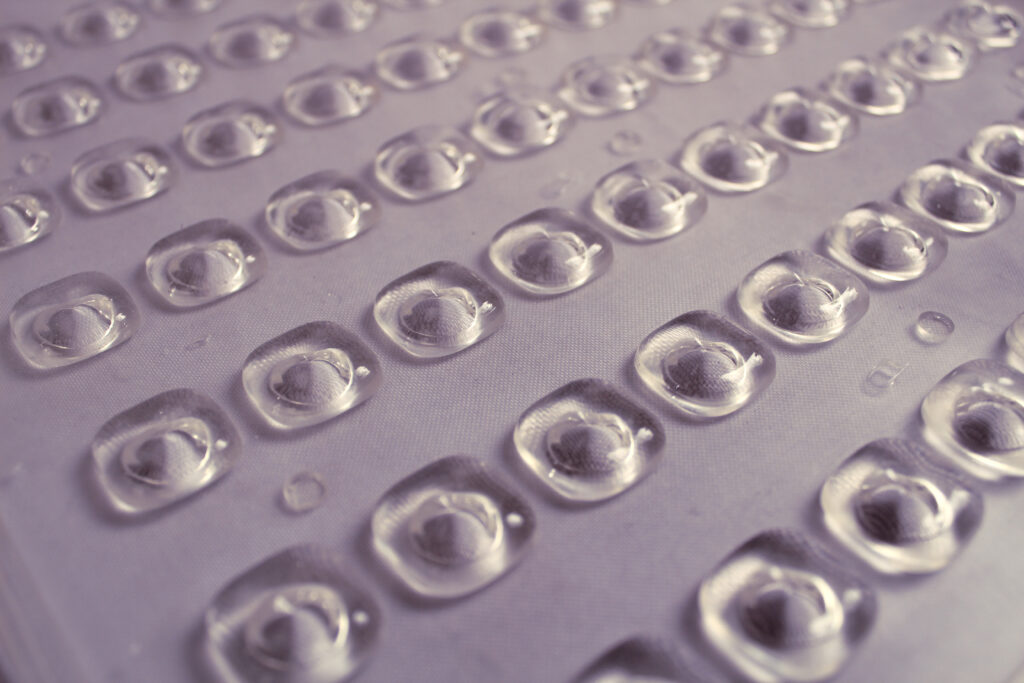

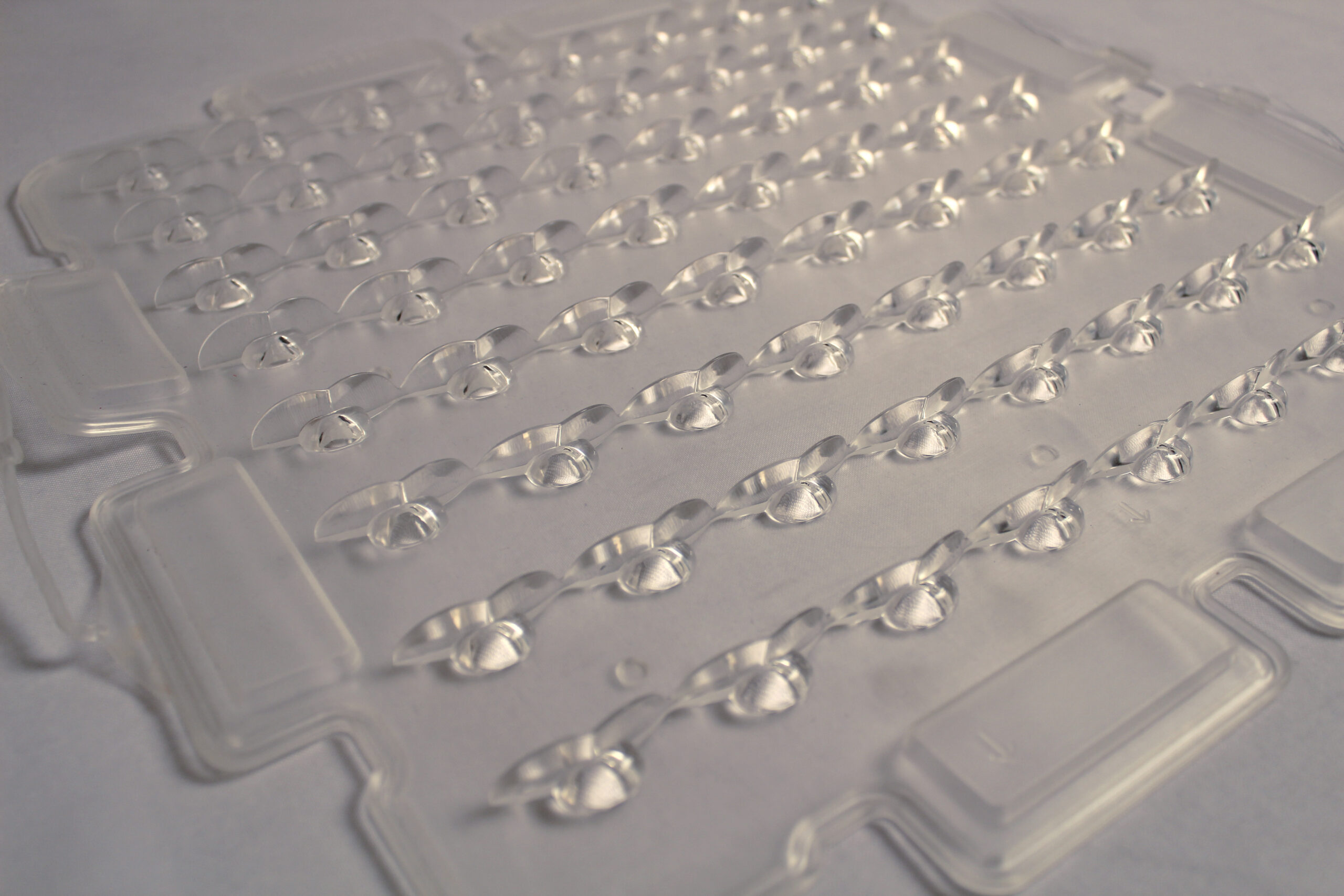

When selecting a silicone molder for your optical components, several critical factors can impact quality, production speed, and overall cost-effectiveness. A.L.P. brings industry-leading expertise and cutting-edge technology to optical silicone molding, ensuring high precision and rapid turnaround. Here are key considerations to guide your selection process.

Capacity

A.L.P. LexaLite® offers an extensive lineup of seven Liquid Silicone Rubber (LSR) injection molding machines to accommodate projects of various sizes and complexities:

• 80-ton

• 180-ton

• 220-ton

• Three 240-ton

• 660-ton

Advanced Technology

Our state-of-the-art injection molding equipment includes essential production enhancements:

• Built-in conveyor systems for streamlined handling

• Electro Servo injection technology for superior control

Unique Molding Capabilities

With the capacity to mold parts up to approximately 200 square inches, our equipment is ideal for a wide range of optical applications. The low viscosity of Liquid Silicone Rubber requires molds built with extremely tight tolerances to prevent leaks, ensuring the highest precision in molded components.

In-House Tooling Resources

A.L.P. maintains high-speed machining centers and advanced surface grinding capabilities, allowing us to produce critical tooling in-house. This capability significantly reduces lead times and enhances quality control throughout production.

Rapid Prototyping

Speed to market is crucial in today’s competitive environment. Our precise machining processes minimize the need for extensive polishing, allowing us to produce production-ready inserts in weeks rather than months. This streamlined approach ensures faster prototype iterations and accelerated product development.

Materials Expertise

With over a decade of experience in optical silicone molding, our team has extensive knowledge of LSR materials. We understand the unique molding requirements of optical-grade silicones and engineering molds with the precision necessary to prevent leakage and maintain part integrity.

In-House Testing for Quality Assurance

To guarantee superior product performance, we offer:

• Photometry Lab: Enables real-time evaluation of first-run samples

• Optical Coordinate Measuring Machine (CMM): Ensures molded parts meet precise design specifications

Partner with A.L.P. LexaLite® for Optical Silicone Molding Excellence

With our cutting-edge silicone molding technology, in-house tooling expertise, and commitment to quality, A.L.P. is your ideal partner for bringing optical silicone molding projects from concept to production—quickly and efficiently.

A.L.P., In-house Tooling, injection molding, LexaLite, Liquid Silicone Rubber, LSR, Moldable Optical Silicone (MOS), Optical Silicone, Rapid Prototyping, Silicone Molder

Why Silicone is Revolutionizing Optical Molding

In the world of precision optics, choosing the right material for your molding project can significantly impact performance, durability, and efficiency. Optical silicone molding is emerging as a game-changer, offering advantages that surpass traditional thermoplastics. A.L.P. provides industry-leading expertise in optical silicone molding, combining advanced equipment, tooling, and optical engineering to deliver high-quality solutions. Our in-house photometry lab enables real-time evaluation of first samples, ensuring optimized results from concept to production.

The Advantages of Optical Silicone Molding

When selecting materials for optical applications, Moldable Optical Silicone (MOS) stands out due to its unique properties. Here’s why optical silicone is revolutionizing the industry:

Superior Optical Clarity and Light Transmission

• Optical silicone provides greater than 91% light transmittance, ensuring maximum efficiency in lighting and optical applications.

• A refractive index of 1.41, it enables high-performance optical designs.

Exceptional Moldability and Precision

• Its low viscosity allows for excellent mold replication, capturing fine details with precision.

• Unlike thermoplastics, silicone requires low clamp tonnage, reducing production costs and complexity.

• Negative draft (undercut) features can be achieved with optical silicone, making it highly versatile for complex geometries.

Unmatched Durability and Environmental Resistance

• Silicone offers an exceptional continuous service temperature range from -45°C to +200°C, maintaining stability in extreme conditions.

• Most optical silicone grades are immune to UV degradation, ensuring long-lasting performance without yellowing or material breakdown.

• Exceptional impact resistance makes it ideal for rugged applications.

Versatility in Molding and Integration

• Insert molding capabilities with plastic, metal, and glass allow for integrated component manufacturing.

• Silicone expands when molded, allowing for thicker wall sections with no sink marks, a common issue with thermoplastics.

• Its ability to provide self-gasketing and self-mounting functionalities reduces the need for additional components and assembly steps.

Why Choose A.L.P. for Optical Silicone Molding?

A.L.P. stands at the forefront of optical silicone molding, leveraging cutting-edge equipment, innovative engineering, and a dedicated in-house photometry lab. Our expertise ensures:

• Rapid prototype development and testing

• Precision molding with complex geometries

• Reliable, high-performance optical solutions for demanding applications

If you’re considering optical silicone molding for your next project, A.L.P. is your trusted partner. Contact us today to learn how we can help bring your vision to life with industry-leading silicone molding solutions.

A.L.P., Enhanced LED Performance, Exceptional Moldability and Precision, high-performance optical solutions for demanding applications, immune to UV degradation, LED, LexaLite, Moldable Optical Silicone (MOS), Precision molding with complex geometries, precision optics, Rapid prototype development and testing, Reliable, Superior Optical Clarity and Light Transmission, Unmatched Durability and Environmental Resistance, Versatility in Molding and Integration

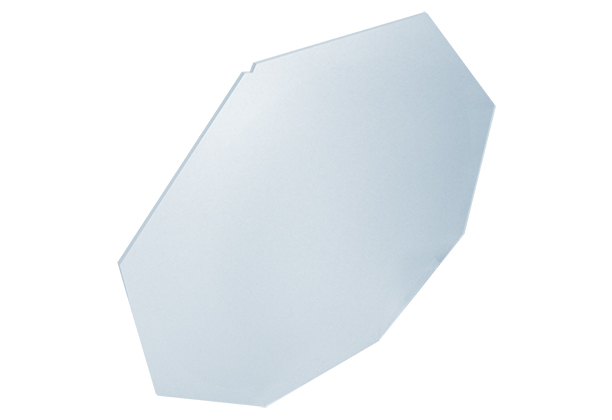

A.L.P. Introduces Octagonal Large Area Edgelit Panel for Commercial Fixtures

Niles, IL – A.L.P., a leader in innovative lighting solutions, announces a new commercial lighting optic, the Octagonal Large Area Edgelit Panel. This newly designed lens offers OEMs a combination of performance, efficiency, and versatility.

A.L.P.’s Octagonal Large Area Edgelit Panel is engineered for a variety of commercial applications, such as parking garages and similar settings. The panel’s wide beam angle produces uniform and glare-free illumination, ensuring optimal visibility and comfort. Featuring an octagonal shape with a centered round optic, the panel’s slim profile allows it to be used with rigid LED boards to facilitate alignment and heat sinking.

Injection molded from acrylic for durability and UV resistance, the octagonal panel offers reliability and performance for many commercial fixture designs. It also can be laser cut to smaller finished sizes on request.

“The Octagonal Large Area Edgelit Panel was designed with visual comfort in mind,” said Tom Barnes, Vice President and Business Manager. “We are pleased to offer a solution that prioritizes performance, efficiency, and design versatility for lighting OEMs.”

A.L.P., Injection Molded, LexaLite, Octagonal Large Area Edgelit Panel, Parking Garage, wide beam angle

A.L.P.’s Lindy® and Lineman™ Post-Top Optics Offered in Two Pieces

Simple solution saves time, freight, and cost

A.L.P. offers two of its Industry-leading post-top optics in two pieces to simplify installation and save you money.

Freight costs can be lowered dramatically, with refractor tops and caps nested and shipped separately, cutting the weight and size of bulkier shipments. Assembly is easy and can be done on-site without tools.

Lineman™ also is offered with optional caps and finials, allowing you to expand your product offering easily and inexpensively.

In addition to saving money, the Lindy® and Lineman post tops outperform other one-piece solutions for roadways, walkways, parks, and residential outdoor lighting. Their outstanding features and benefits include:

• Visually pleasing

• Compatible with HID or LED

• Lower glare

• Durable

• UV stable

• Impact resistant

• Material choices

• 8” or 9” necks

• Optional accessories

A.L.P., Acrylic, Clear Acrylic, Clear Polycarabonate, HID, injection molding, LED, LexaLite, Lindy, Lineman, Lumieo Acrylic, Post Top, refractor tops, residential outdoor lighting, UV Stable

New Post-Top Combinations to Expand Your Product Line

Fewer SKUs, Cheaper Freight, Lower Overall Cost

A.L.P.’s newest post-top lighting innovation allows our model 401 Lineman™ top and cap to be used with our industry-leading model 425 Lindy® bottom, so you can add to the variety of your traditional street and area lighting while cutting costs and keeping SKUs to a minimum.

The secret is in the design of Lineman’s injection molded top and cap. Using a snap-fit feature, it is attached in the field without tools. The top and bottom optics are shipped separately, dramatically reducing freight costs up to 70 percent versus pre-assembled post tops and eliminating the need—and cost—of attaching clamp bands.

This interchangeable option combines the look and performance of the Lindy with the value of the Lineman, adding variety to your product offering with the most economical, environmentally friendly approach. Other new options include new black acrylic tops for some Lineman and Lindy configurations.

All Lindy and Lineman acrylic post tops come with a 10-year warranty against discoloration. Why wait when you can add variety and lower costs with a classic post-top aesthetic and superior performance?

A.L.P., Black Acrylic, injection molding, Interchangeable, LexaLite, Lindy 425, Lineman 401, Lumieo, Polycarbonate, Post Top, Post-Top Combinations, Post-Top Configurator, Snap-fit, Street and Area Lighting