A.L.P. Introduces the Lineman™ Utility Grade Post-Top Globe

(Niles, IL) A.L.P. is pleased to announce the introduction of the Lineman™, a new utility-grade post-top globe. Designed to illuminate walkways, parks, and roadways, the Lineman features a nostalgic, turn-of-the-century shape with modern material choices for an economical alternative to other performance globes.

It is versatile, attractive, and affordable. The Lineman features a configurable top so that the appearance can be customized for any application. In addition, multiple finished shapes can be created by adding cap or finial options.

This new utility-grade post-top is easy to install and maintain. The innovative locking design allows the top and bottom to be efficiently shipped and then permanently field assembled with no tools. Manufactured in acrylic for longevity without discoloration, the Lineman is compatible with LED lamp sources and poles with a height of 10’ to 20’.

The Lineman is the latest addition to the 400 Series injection molded post-tops from the A.L.P. LexaLite brand. It can be shipped economically in two or three pieces. In addition, it has the same maximum diameter (15.9”) as A.L.P.’s popular The Lindy® refractor, offering the potential for component sharing.

For OEM and retrofit applications, A.L.P.’s traditionally styled Lineman post-top globe is a less expensive alternative to other performance optics that does not compromise on the durability and versatility integral to the 400 Series.

400 Series, A.L.P., Acrylic, configurable top, finial, Globe, Injection Molded, LexaLite, Lineman, Little Lindy, Lumieo Acrylic, Parks, performance globes, Polycarbonate, Post Top, Post Top Family, Post-top, post-top globe, Prismatic Post Top, refractor, Retrofit Applications, Roadways, Utility Grade, Walkways

Press Release: A.L.P. Introduces the Sentry® Barricade™ Lens for Outstanding Vaportight Performance

(Niles, IL) A.L.P. Lighting Components is pleased to announce the introduction of Sentry® Barricade™, a new 4-ft injection-molded low-profile lens. It is the newest addition to A.L.P.’s line of rugged lenses for the flagship Sentry® Series enclosed and gasketed fixture kits. Featuring a contemporary look and outstanding performance, the new lens modernizes the Sentry Series line while maintaining the existing benefits of robust construction and a large compartment size.

Designed by the injection molding experts from A.L.P. LexaLite®, Sentry Barricade’s molded-in texture offers superior lamp hiding. In addition, a new gasket compression rib results in superior sealing for extreme environments.

The Sentry Barricade lens is available in clear acrylic, Lumieo® (frosted acrylic), and clear polycarbonate. Regardless of the light source, the clear and Lumieo options provide visual comfort while maintaining high efficacy. The clear polycarbonate version will stand up to applications requiring impact resistance and is a more economical choice than A.L.P.’s current thermoformed offering.

Suspended vaportight Sentry enclosures are suitable for wet, damp, dusty, and cold applications such as parking garages, car washes, industrial buildings, and horticultural spaces. Samples are available now.

A.L.P., Barricade, Barricade Lens, car washes, Clear Polycarbonate, damp applications, dusty applications, gasket compression rib, Gasketed Enclosure, horticultural spaces, industrial buildings, injection molding, LexaLite, Lumieo Acrylic, parking garages, Sentry Barricade Lens, Sentry Series, superior sealing, Vapor Tight, vaportight, wet applications

Press Release: A.L.P. Introduces DASSL™ Surgical Lighting Lens

(Niles, IL) Lighting is critical in surgical settings to maximize visibility, minimize eye fatigue, and enable the medical team to focus on the surgical operation. A.L.P. recently introduced the DASSL™ (Diffuse Asymmetric Symmetric Surgery Lens) for recessed or surface mounted luminaires in operating rooms.

The new biased diffuse microstructure lens provides improved LED hiding power, smooth distribution, and both symmetrical (along axis) and asymmetrical (cross axis) lighting distributions. This optical distribution directs more light on a targeted work surface. Unlike linear optic lenses, lamp alignment has less impact on distribution.

“Surgical lighting is overdue for optical improvements,” states Tom Barnes, Vice President and Business Unit Manager for A.L.P.’s LexaLite brand. “DASSL lenses replace traditional linear prismatic lenses by taking advantage of microstructure optics,” he adds.

DASSL lenses are designed for 2’ x 4’ fixtures, but custom sizes are also available. An optional RFI shielding grid also is offered to protect from electromagnetic interference. RFI Shielding allows fixtures to comply with the MIL-STD-461(E) standard. Samples are now available.

Asymmetric, Custom Sizes, DASSL, electromagnetic interference, LED Hiding, LexaLite, microstructures, MIL-STD-461(E) Standard, optical distribution, RFI Shielding, Surgical Lighting Lens, Symmetric

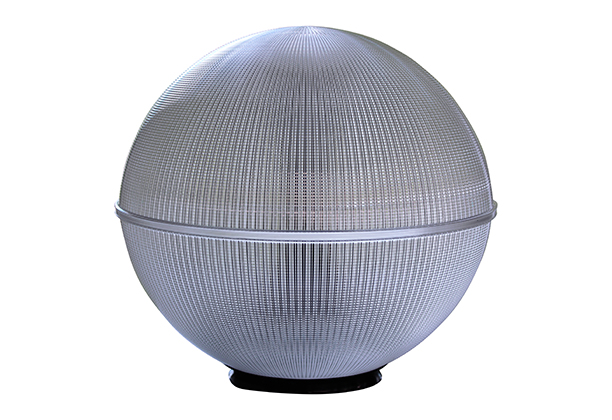

Press Release: A.L.P. Introduces the Rayder™, a Modern, High-Performance Prismatic Post-Top Sphere

(Niles, IL) -A.L.P. Lighting Components, a leading global manufacturer of lighting components and kits, has added the Rayder™ post-top prismatic sphere to its 400 Series injection molded optics for outdoor lighting. The Rayder is designed to deliver a uniform distribution, higher efficiency, improved CRI, outstanding glare control, and a timeless appearance.

Today’s new post-top installations and retrofits need to be energy efficient, aesthetically pleasing, and provide safe illumination of walkways and streets. The Rayder excels in applications where brightness control is a priority. The Rayder’s optics reduce high angle glare and hide LED light sources while delivering a uniform glowing appearance. The Rayder also offers a significant improvement in efficiency when compared to diffuse or translucent blow molded spheres.

Suitable for 10′ – 20′ poles, the assembled spheres are 19.2″ in diameter, and are available with either 8″ diameter neck or other custom bottom openings. The Rayder is offered in Clear Optical Acrylic, Diffuse Acrylic, and Clear Polycarbonate. The top and bottom halves are easily attached using the affixed UV stable high bond double-sided adhesive ribbon for fast assembly and mounting. Acrylic versions are covered by a ten-year limited warranty.

“Optical glare control and the delivery of IES distributions are paramount features of A.L.P. LexaLite’s post top and dusk-to-dawn refractors,” says Kurt Puffpaff, National Sales Manager for Proprietary Products. “Utilizing A.L.P.’s existing optical prescriptions will increase efficiency, reduce glare and deliver light where light is needed,” he states. “Many fixtures incorporate white or diffuse lenses or no lenses at all. Applying A.L.P.’s optical component will improve fixture performance and application effectiveness,” Puffpaff concludes.

A.L.P. is a leading global supplier of lighting components, offering a diverse line of products and services for lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. offers the industry’s most comprehensive line of LED fixture kits, vapor-proof enclosures, unwired fixture bodies, louvers, and reflectors. A.L.P. Brands include Steel Craft, LexaLite®, and Reflek®

400 Series, A.L.P., Glare Control, High-performance, Injection Molded, LexaLite, Outdoor Lighting, Post-top, Prismatic, Rayder, Sphere, uniform distribution

Press Release: A.L.P. Produces PPE Face Shields for COVID-19 Health Care Workers

Joining the fight against the COVID-19 pandemic, the injection molding team at A.L.P. LexaLite’s Charlevoix, MI facility mobilized to design and manufacture Personal Protective Equipment (PPE) face shields for front-line health care workers. They rapidly reorganized tooling and manufacturing functions to support this critical need, and they expect to have the first production models coming off the presses within days.

The company was initially approached by Charlevoix Hospital, looking for PPE. While primarily a manufacturer supplying components for lighting fixtures, A.L.P. has several customers in the health care sector. The team drew on its knowledge of health care requirements and standards to quickly design and tool the face shields in an unprecedented 10-day turnaround.

When in full production, A.L.P. can produce approximately 1400 face shields per day, and they plan to sell them at cost. “We will make them as long as they are needed,” states Steve Brown, CEO.

“This is one scenario I didn’t see coming,” Brown adds. “The COVID-19 crisis is tragic, yet it shows us what we can accomplish together when needed,” he observes. A.L.P. is not alone, as manufacturers all over the country are making similar efforts.

The A.L.P. face shield has some unique features. The plastic shield snaps onto a headband, and the shield is disposable. So, the caregiver can use the same headband throughout the day and simply snap on a new shield for each patient.

A.L.P. continues to operate during this crisis as an Essential Business, supplying into vital infrastructure such as construction, health care, transit, and government. The company has adjusted its practices, with the health and safety of employees, families, and communities as a top priority. The A.L.P. staff is working remotely when possible. All manufacturing locations have implemented additional measures to ensure safe distancing of employees, such as adjusting schedules, spacing equipment, and reorganizing meeting and break room spaces.

Charlevoix, COVID-19, disposable shield, Essential Business, headband, Health Care Workers, injection molding, LexaLite, Personal Protective Equipment, PPE Face Shields, tooling

Press Release: A.L.P. Introduces LENA 16™, a Cost-Effective, High Performing, Low Profile Reflector

(Niles, IL) -A.L.P. Lighting Components, a leading global manufacturer of lighting components and kits, has added the LENA 16™ shallow prismatic reflector to the “S Series” of optics. Designed for low-, mid- and high-bay LED fixtures, it offers superior glare control and an elegant aesthetic, combined with the versatility to accommodate a variety of light sources without expensive modifications.

The LENA 16 has a shallow design, optimizing cost without sacrificing high angle brightness control. The 10.36” flat top allows it to be easily adapted and directly attached to many fixtures. The lower flange works with a wide range of bottom lenses and standard clamp bands. The top can be cut to order with an opening of up to 10.66 inches.

Like their HID predecessors, today’s LED low-, mid- and high-bay fixtures should always be installed with optical or refractive control. Without this control, they emit high angle glare, causing a reduction in contrast and negatively affecting color and focus. By reducing high angle glare, LENA 16 improves visual comfort, provides even illumination, and can also increase worker efficiency in some settings. It is suitable for warehouse, industrial, commercial, and retail applications.

LENA 16 is available in Clear Acrylic, Clear Polycarbonate, Interface Acrylic, and Lumieo® Acrylic. It works with a wide range of LexaLite® brand bottom lenses.

A.L.P. is a leading global supplier of lighting components, offering a diverse line of products and services for lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. offers the industry’s most comprehensive line of LED fixture kits, vapor-proof enclosures, unwired fixture bodies, louvers and reflectors. A.L.P. Brands include Steel Craft, LexaLite®, and Reflek®

Clear Acrylic, Clear Polycarabonate, High Bay, Interface Acrylic, LED, LENA 16, LexaLite, Low Bay, Lumieo Acrylic, Mid Bay, Reflector, Reflexor, Shallow