7 Things to Know Before You Choose Suspension Hardware

When designing a fixture, it’s easy to focus on performance or looks—but suspension is just as critical. The right suspension ensures safety, simplifies installation, and enhances overall design.

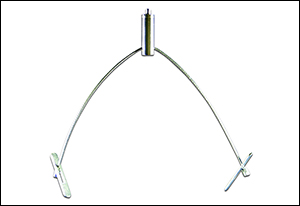

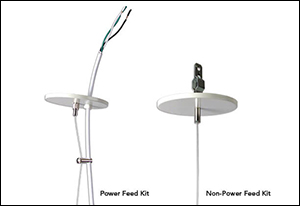

A.L.P. offers a complete portfolio of suspension solutions, including Single-Point, V Hook, Universal Yoke and Toggle, canopy kits, and custom-length tethers. But how do you choose the best option for your project?

Here are seven vital considerations:

- Safety First – Load capacity, strength, and certifications

- Aesthetic Fit – How suspension complements design appearance

- Ease of Installation – Saving time for contractors

- Flexibility & Adjust ability – Accommodating various ceiling heights and fixture weights

- Compatibility – Options including Single-Point, V Hook, Yoke/Toggle, canopy kits, and custom lengths

- Compliance – Meeting UL/ETL requirements and regional standards

- Customization – Tailored solutions with custom tethers and kits

Interested in stronger, safer, smarter fixture suspension?

Canopy Kits, Compliance, Safety, Single-Point, Suspension Hardware, Suspension kits, Suspension Solutions, Suspension Systems, Tethers, Universal Yoke and Toggle, V Hook

Key Considerations When Choosing a Silicone Molder

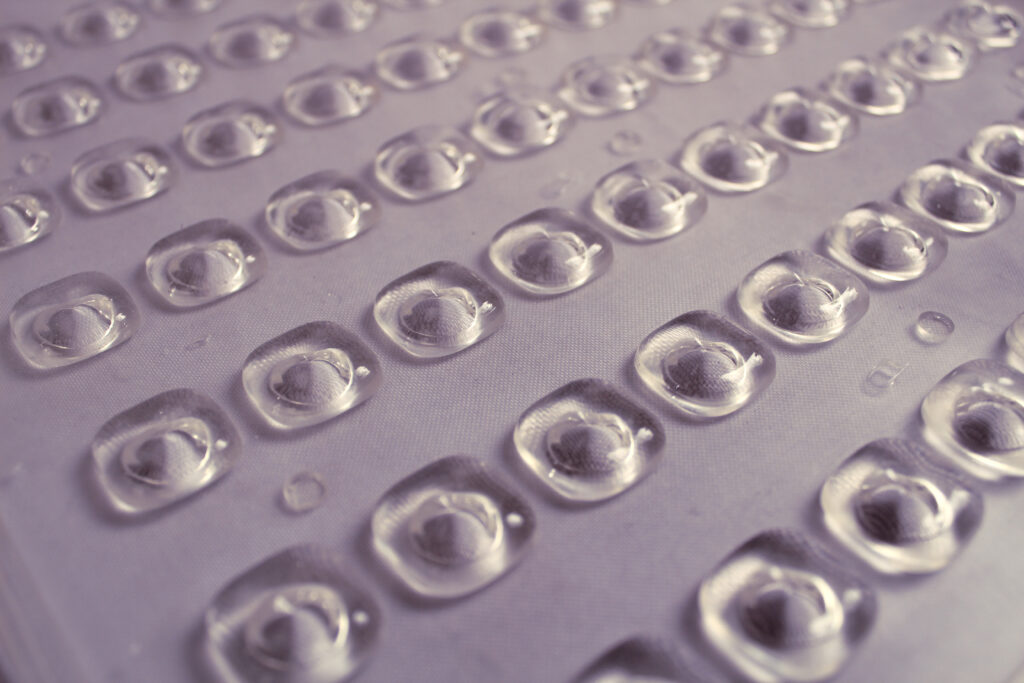

Optimizing Optical Silicone Molding for Performance and Efficiency

When selecting a silicone molder for your optical components, several critical factors can impact quality, production speed, and overall cost-effectiveness. A.L.P. brings industry-leading expertise and cutting-edge technology to optical silicone molding, ensuring high precision and rapid turnaround. Here are key considerations to guide your selection process.

Capacity

A.L.P. LexaLite® offers an extensive lineup of seven Liquid Silicone Rubber (LSR) injection molding machines to accommodate projects of various sizes and complexities:

• 80-ton

• 180-ton

• 220-ton

• Three 240-ton

• 660-ton

Advanced Technology

Our state-of-the-art injection molding equipment includes essential production enhancements:

• Built-in conveyor systems for streamlined handling

• Electro Servo injection technology for superior control

Unique Molding Capabilities

With the capacity to mold parts up to approximately 200 square inches, our equipment is ideal for a wide range of optical applications. The low viscosity of Liquid Silicone Rubber requires molds built with extremely tight tolerances to prevent leaks, ensuring the highest precision in molded components.

In-House Tooling Resources

A.L.P. maintains high-speed machining centers and advanced surface grinding capabilities, allowing us to produce critical tooling in-house. This capability significantly reduces lead times and enhances quality control throughout production.

Rapid Prototyping

Speed to market is crucial in today’s competitive environment. Our precise machining processes minimize the need for extensive polishing, allowing us to produce production-ready inserts in weeks rather than months. This streamlined approach ensures faster prototype iterations and accelerated product development.

Materials Expertise

With over a decade of experience in optical silicone molding, our team has extensive knowledge of LSR materials. We understand the unique molding requirements of optical-grade silicones and engineering molds with the precision necessary to prevent leakage and maintain part integrity.

In-House Testing for Quality Assurance

To guarantee superior product performance, we offer:

• Photometry Lab: Enables real-time evaluation of first-run samples

• Optical Coordinate Measuring Machine (CMM): Ensures molded parts meet precise design specifications

Partner with A.L.P. LexaLite® for Optical Silicone Molding Excellence

With our cutting-edge silicone molding technology, in-house tooling expertise, and commitment to quality, A.L.P. is your ideal partner for bringing optical silicone molding projects from concept to production—quickly and efficiently.

A.L.P., In-house Tooling, injection molding, LexaLite, Liquid Silicone Rubber, LSR, Moldable Optical Silicone (MOS), Optical Silicone, Rapid Prototyping, Silicone Molder

A.L.P. Monterrey Earns ISO 9001:2015 Certification, Enhancing Quality and Value for Customers

A.L.P. is proud to announce that our Monterrey, Mexico manufacturing facility has achieved ISO 9001:2015 certification, a globally recognized benchmark for quality management systems. This certification underscores our unwavering commitment to delivering reliable, high-quality products and services to our customers. For customers across lighting, medical, automotive, appliance, and mass transportation industries, the certification offers added assurance that A.L.P. Monterrey meets rigorous international standards for quality, efficiency, and continuous improvement.

“This is more than a milestone—it’s a reflection of our team’s dedication to operational excellence and our strategic focus on being a trusted partner to OEMs,” states Adam Mayse, A.L.P.’s President and COO.

The Monterrey facility is strategically located in one of Mexico’s key manufacturing corridors, offering proximity to major customers and suppliers. Capabilities at this location include injection molding, compression molding, optical silicone molding, and metal fabrication.

Congratulations to the entire Monterrey team for their hard work and focus in achieving this important certification—another step forward in strengthening A.L.P.’s value to our customers.

A.L.P., Appliance, Automotive, Certification, continuous improvement, efficiency, ISO 9001:2015, Lighting, mass transportation, Medical, Mexico, Monterrey, quality, Quality Management System

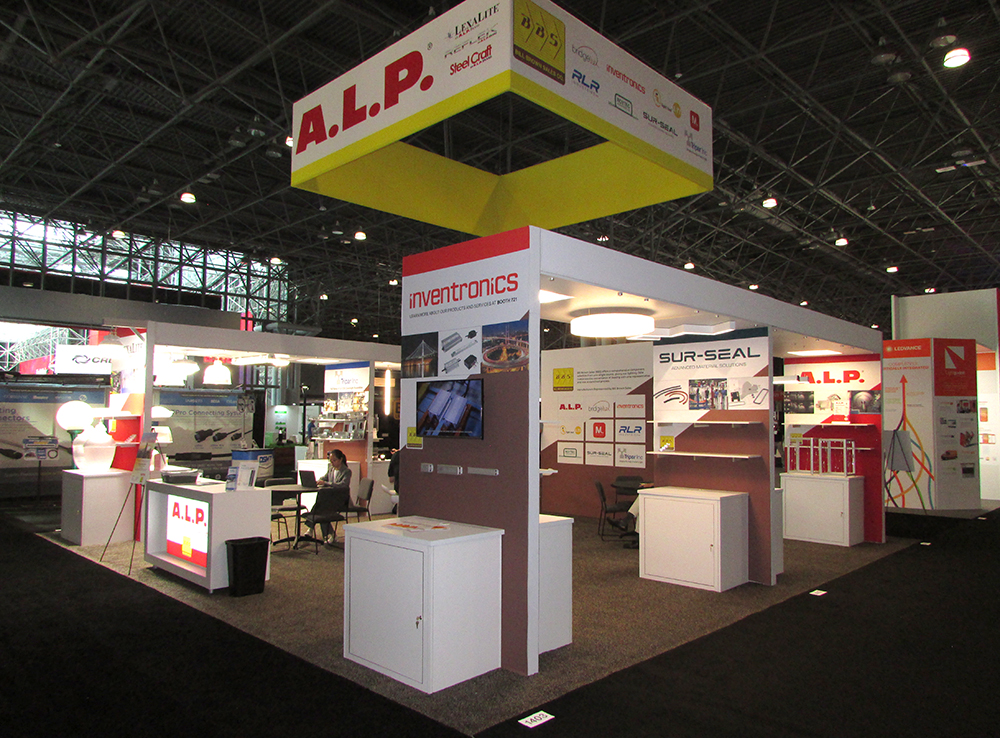

Meet A.L.P. at 2025’s Top Lighting Trade Shows!

See You at the Show!

A.L.P. is excited to showcase our extensive catalog of lighting components and custom manufacturing capabilities at several premier U.S. lighting industry trade shows in 2025.

We understand the importance of in-person interactions. Before investing in components for your fixture design, it’s essential to see them, test them, and ensure they meet your exact objectives. Similarly, when selecting a partner for custom-molded optical components or fabricated metal parts, sitting down with manufacturing experts is key to building trust and confidence.

With corporate travel budgets tighter than ever, making the most of your time and resources is critical. That’s why the A.L.P. team is committed to maximizing the value of your trade show visits. We’re bringing our best innovations and brightest experts to these industry-leading events:

LEDucation | March 18–19, 2025 | New York, NY

Lightfair International | May 4–8, 2025 | Las Vegas, NV

IES25—The Lighting Conference | August 21–23, 2025 | Anaheim, CA

IES Street and Area Lighting Conference | September 21–24, 2025 | New Orleans, LA

We’d love to connect with you at these shows! Visit our booth to explore our products, meet our team, and discover how we can support your projects. To ensure dedicated time with us, contact your regional sales manager to schedule a one-on-one appointment. If you’re planning to attend, let A.L.P. help make your trip worthwhile!

A.L.P. is a leading global supplier of lighting components, providing a diverse portfolio of products and services tailored to the needs of lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. delivers the industry’s most comprehensive range of optical components, LED fixture kits, custom services, and more. With over 40 years of experience, A.L.P. continues to set the standard for quality and innovation. The company’s premier brands, including LexaLite® and Steel Craft, are trusted worldwide for their performance and reliability.

A.L.P., aftermarket, Custom Manufacturing, IES Street and Area Lighting, IES25, LED Fixture Kits, LEDucation, LexaLite, Lightfair International, Lighting, Lighting Components, OEMs, Optical Components, SteelCraft

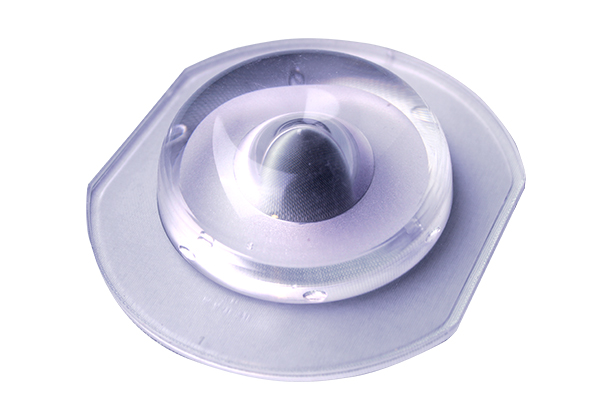

New Silicone TIR Optic for Outdoor Lighting is Virtually Indestructible

Delivers 91% light transmission without sacrificing durability or performance.

A.L.P. is pleased to introduce the new 1100 Series, a Type V Total Internal Reflection (TIR) optic optimized for COBs with a Light Emitting Surface of up to 18mm. Designed for use in outdoor lighting or other high-power applications, the optical-grade Liquid Silicone Rubber (LSR) optic provides excellent transmittance, impact resistance and high temperature operation while being immune to UV degradation. The 1100 Series offers 65-degree beam distribution, allowing for greater spacing while maintaining uniformity.

Its flange provides mounting features that are compatible with off-the-shelf frames, and bottom side of the optic includes mounting alignment features.

PERFORMANCE HIGHLIGHTS:

“18-V-W”: 18mm LED / type 5 (V) / Wide beam distribution

Designated LED size: 18

Light distribution type: V (5)

Beam description: Wide

FEATURES & BENEFITS

- Excellent uniformity

- Unlimited service lifetime

- Mounting features matching other off-the-shelf optics

- Greater than 91% light transmittance

- Continuous service temperature range -45 to +200º C

- Impact, chemical and UV resistant

In addition to manufacturing the innovative 1100 Series, A.L.P. has unsurpassed capacity and expertise in optical silicone molding. We can produce custom silicone components quickly and cost effectively, in either Charlevoix, MI or Monterrey, MX, with 80-ton, 180-ton, 220-ton, 240-ton and 660-ton press capacities.

Contact your Bill Brown Sales regional manager for more information.

1100 Series, 18mm, A.L.P., COBs, LexaLite, Liquid Silicone Rubber, LSR, optical-grade, Outdoor Lighting, Silicone Optic, TIR Optic

Generate incremental revenue FAST with troffer component kits from A.L.P.

A.L.P. has teamed up with RLR Industries to create a family of four troffer component kits that can help you quickly drive incremental revenue without tying up the resources and time needed to develop your own fixture line.

The ELFT kits leverage architectural troffer diffusers from RLR with A.L.P.’s proven, durable EL housings and door frames. Offered in standard 2’x2’ and 2’ x 4’ sizes, they also feature a new externally mounted driver compartment, resulting in an uncluttered fixture housing cavity that improves performance, versatility, and contributes to the shadow-free illumination of the thermoformed diffuser.

The uniformly luminous, evenly diffused component sets produce a specification grade troffer with visual sculpture and depth. The diffusers are offered in four design themes that emulate popular architectural design trends, so the troffers are suitable for applications across a variety of commercial spaces.

ELFT3 Curved Ribbed Center Troffer Luminaire

Component Kit 2×2 and 2×4

ELFT10 Curved Body Troffer Luminaire

Component Kit 2×2 and 2×4

ELFT13 Flat Center Troffer Luminaire

Component Kit 2×2 and 2×4

ELFT15 Concave Body Troffer Luminaire

Component Kit 2×2 and 2×4

VERSATILE SOLUTIONS YOUR CUSTOMERS NEED NOW!

• Diffuser features proprietary blend of LED acrylic and impact acrylic resins

• Light transmission approximately 75% with excellent pixel hiding

• Driver is mounted outside the fixture cavity in a spec grade driver box with multiple wiring entry points

• Complete access to the driver compartment available from the floor side of the installed unit

• ELFT 3, ELFT10, ELFT15 designed for use with Emitter LED boards (not provided)

• ELFT13 designed for use with Standard LED boards (not provided)

• Made in America, short lead times

Get your new troffer product line up and running quickly, because we’ve done the work for you! Generate profits quickly with these proven luminaire designs. Your Bill Brown Sales regional manager has all the details.

A.L.P., Diffuser, ELFT, ELFT10, ELFT13, ELFT15, ELFT3, RLR Industries, troffer, troffer component kits