Press Release: A.L.P. Introduces the Sentry® Barricade™ Lens for Outstanding Vaportight Performance

(Niles, IL) A.L.P. Lighting Components is pleased to announce the introduction of Sentry® Barricade™, a new 4-ft injection-molded low-profile lens. It is the newest addition to A.L.P.’s line of rugged lenses for the flagship Sentry® Series enclosed and gasketed fixture kits. Featuring a contemporary look and outstanding performance, the new lens modernizes the Sentry Series line while maintaining the existing benefits of robust construction and a large compartment size.

Designed by the injection molding experts from A.L.P. LexaLite®, Sentry Barricade’s molded-in texture offers superior lamp hiding. In addition, a new gasket compression rib results in superior sealing for extreme environments.

The Sentry Barricade lens is available in clear acrylic, Lumieo® (frosted acrylic), and clear polycarbonate. Regardless of the light source, the clear and Lumieo options provide visual comfort while maintaining high efficacy. The clear polycarbonate version will stand up to applications requiring impact resistance and is a more economical choice than A.L.P.’s current thermoformed offering.

Suspended vaportight Sentry enclosures are suitable for wet, damp, dusty, and cold applications such as parking garages, car washes, industrial buildings, and horticultural spaces. Samples are available now.

A.L.P., Barricade, Barricade Lens, car washes, Clear Polycarbonate, damp applications, dusty applications, gasket compression rib, Gasketed Enclosure, horticultural spaces, industrial buildings, injection molding, LexaLite, Lumieo Acrylic, parking garages, Sentry Barricade Lens, Sentry Series, superior sealing, Vapor Tight, vaportight, wet applications

Press Release: A.L.P. Introduces DASSL™ Surgical Lighting Lens

(Niles, IL) Lighting is critical in surgical settings to maximize visibility, minimize eye fatigue, and enable the medical team to focus on the surgical operation. A.L.P. recently introduced the DASSL™ (Diffuse Asymmetric Symmetric Surgery Lens) for recessed or surface mounted luminaires in operating rooms.

The new biased diffuse microstructure lens provides improved LED hiding power, smooth distribution, and both symmetrical (along axis) and asymmetrical (cross axis) lighting distributions. This optical distribution directs more light on a targeted work surface. Unlike linear optic lenses, lamp alignment has less impact on distribution.

“Surgical lighting is overdue for optical improvements,” states Tom Barnes, Vice President and Business Unit Manager for A.L.P.’s LexaLite brand. “DASSL lenses replace traditional linear prismatic lenses by taking advantage of microstructure optics,” he adds.

DASSL lenses are designed for 2’ x 4’ fixtures, but custom sizes are also available. An optional RFI shielding grid also is offered to protect from electromagnetic interference. RFI Shielding allows fixtures to comply with the MIL-STD-461(E) standard. Samples are now available.

Asymmetric, Custom Sizes, DASSL, electromagnetic interference, LED Hiding, LexaLite, microstructures, MIL-STD-461(E) Standard, optical distribution, RFI Shielding, Surgical Lighting Lens, Symmetric

Do you need to meet the new DLC® Premium requirements?

Are you struggling to meet the Standard requirements? LexaLite® Reflexor® reflectors can help you achieve the glare control numbers you need!

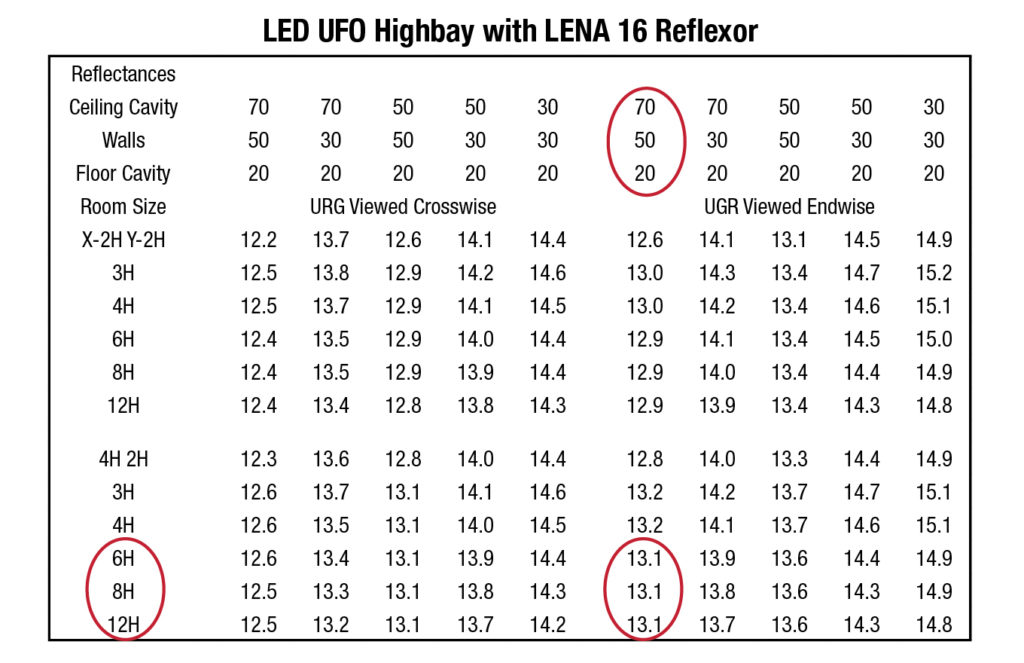

Design Lights Consortium (DLC) evaluates light fixtures against increasingly stringent standards of performance. Most recently, DLC published v5.1, which not only addresses fixture efficacy, color issues, and zonal distribution but also puts a value on glare reduction. The metric used is the Unified Glare Rating (UGR). If you are trying to qualify for DLC Premium, DLC requires that you meet the glare criteria.

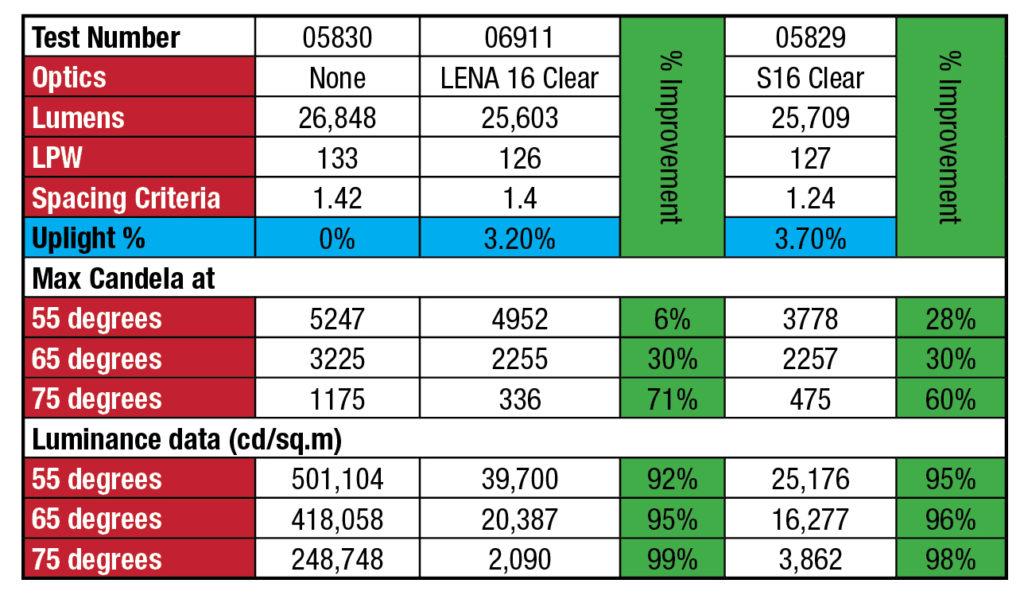

In A.L.P.’s testing, we compared a bare “UFO” highbay with the same fixture adding both our LENA 16™ and S16 reflectors. Using the prescribed criteria, this test yielded the following results: bare UFO =23.9, with LENA 16 = 13.1 and with S16 = 10.9, respectively. Highbays need to be less than 22 to qualify for DLC Premium.

What if you are just struggling to meet DLC Standard LPW for your highbay? DLC now provides a 10% allowance if your fixture meets the criteria for UGR. Adding a prismatic reflector reduces LPW by 3-7%, and you gain 10% with the allowance!

Even the extremely shallow and economical Lena 16 has a significant impact on UGR. Why? It’s just math. Glare is based on several factors, including high angle light, size of the source, and background luminance. Our Reflexors improve all of these factors.

- Reflexors reduce high angle light, providing a shielding angle relative to their depth.

- Bare UFOs are essentially flat luminous surfaces. Reflexors increase the luminous volume dramatically

- Reflexors provide uplight, which increases the background luminance.

These three factors improve visual comfort and make adding a LexaLite Reflexor an easy choice! Make a better highbay while meeting DLC requirements for Glare by using LexaLite Brand Reflexors.

See our entire offering at:

color issues, Design Lights Consortium, DLC, DLC Premium, fixture efficacy, High Bay, Highbays, improve visual comfort, LENA 16, LexaLite, LPW, luminance, reflectors, Reflexor, UFO, UGR, Unified Glare Rating, zonal distribution

Why you should care…about glare!

The importance of reflectors on LED highbays.

Do you ever wear a baseball cap or sunglasses? Ever use your car visor? These shielding actions reduce glare, or “bad” light that detracts from our ability to see. In a factory, warehouse, or retail facility, highbays are installed to light the space, but if the highbays are unshielded, glare interferes with what we can see. In commercial settings, glare is more than an inconvenience. This low visibility can hurt safety, productivity, and health.

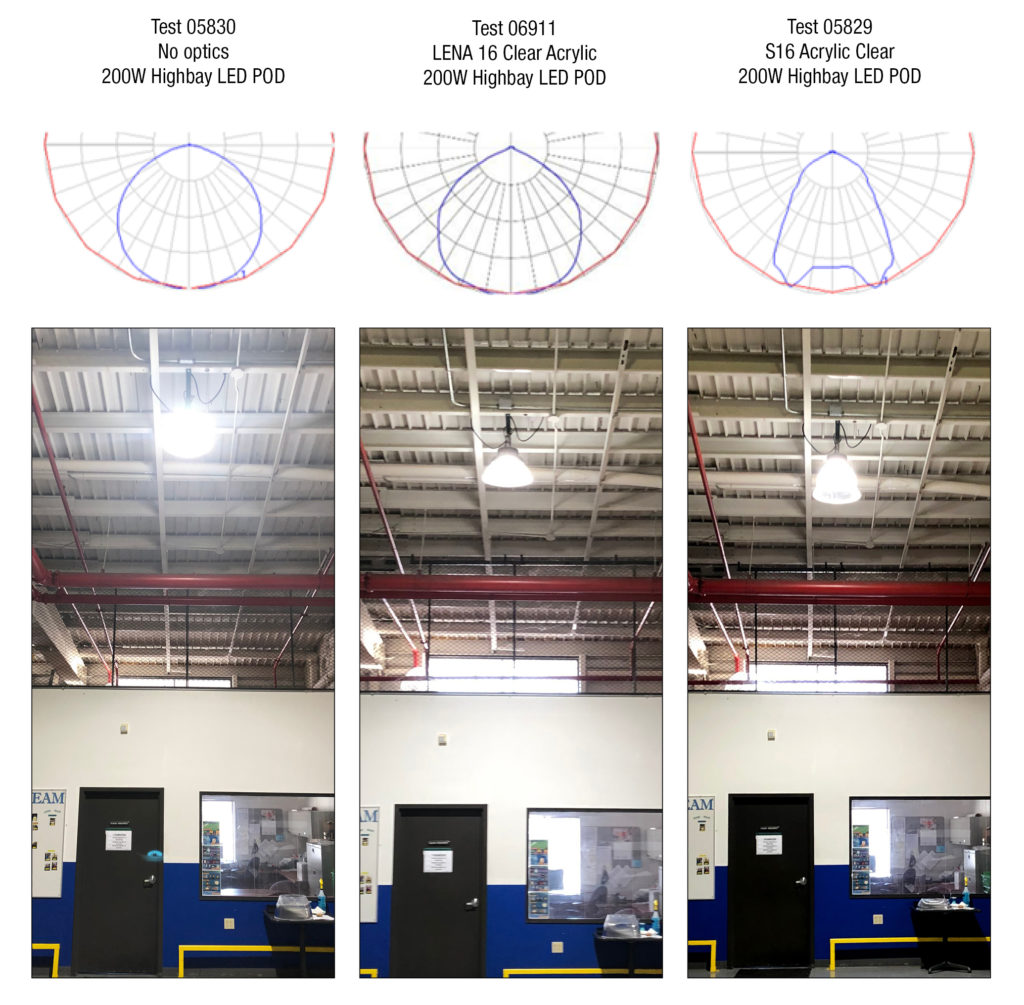

Below are three photometry tests on the same highbay. The first with no reflector, the second with a shallow reflector, and the third with a deeper reflector. The glare reduction, while having little impact on lumen output, is dramatic.

Using a reflector, not only are high angle candela reduced, but they are also emitted over a much larger surface area, reducing high angle luminance by a hundredfold! If your facility has light-colored ceilings, installing reflectors has the added benefit of producing uplight. Uplight further reduces apparent brightness, eliminates the “cave” effect, and makes the space feel larger.

LexaLite® brand glare shields, from the economical and shallow LENA 16™ to the deep, high-performance S16, kill the glare without killing the light. Specify the LENA 16 or S16 by LexaLite on your next highbay project. We can customize the mounting mechanism to fit virtually any highbay.

Deep Reflector, Glare Control, glare reduction, Highbays, LENA 16, LexaLite, Lumen Output, photometry, Reflector, Reflexor, S16, Shallow Reflector, uplight

Meet the Team: Kurt Puffpaff

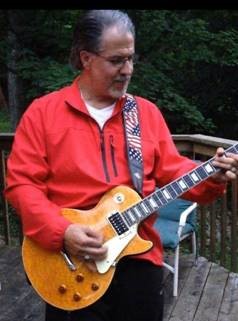

Kurt Puffpaff ROCKS! Though in Kurt’s case, we mean that quite literally. A musician and music aficionado, Kurt plays guitar, sings, and is a huge fan of ‘70s rock bands like AC/DC, Styx and Led Zeppelin. He also writes and records his own original tunes, played on his favorite Birdseye Maple Les Paul guitar. Besides his love for music, Kurt is an avid outdoorsman and a die-hard Kansas City Chiefs fan.

Born and raised in Charlevoix, Michigan, Kurt has moved around the Midwest for his career before returning to his hometown a few years ago and settling with his wife Diane and their four sons, aged from 11 to 22.

Kurt is currently the National Sales Manager for A.L.P.’s custom optical products, but he has been in the lighting industry since 1993. He started his career as a territory manager for LexaLite (now part of A.L.P.) where he learned the business from the ground up, even delivering a few orders by truck when the business depended on it. Drawing on his decades of expertise in injection molding, Kurt can answer almost any molding question that comes his way. You are also invited to pick his brain on classic rock, football, or hunting.

A.L.P., Charlevoix, injection molding, Kansas City Chiefs, Kurt Puffpaff, Les Paul Guitar, LexaLite, musician, National Sales Manager, outdoorsman

Meet the Team: Tom Barnes

Do you know the difference between a jib and a spinnaker? Or where to locate Port and Starboard? You can turn to A.L.P.’s sailing expert, Tom Barnes, for the answer to these puzzling questions and more. When he is not working as Vice President and Business Manager for A.L.P.’s LexaLite® brand, you can find Tom competing in (and often winning) races with the Charlevoix Yacht Club. In addition to sailing, Tom and his wife, Pam, enjoy all that scenic Northern Michigan offers, from golf to hiking and skiing. They are the proud parents of two daughters, Lexie and Abbey.

Tom’s other passion? Plastics! He studied plastics engineering at Ferris State University before joining LexaLite, the company founded by his father, Josh Barnes. Over the years, he held positions in sales, management, operations, and strategic development before joining A.L.P. when LexaLite was acquired in 2007.

In his current role with A.L.P., he is responsible for defining and promoting the plastic optical product line, ensuring profitability by managing product development, production, pricing, and related functions.

A.L.P., Jib, LexaLite, Michigan, Optical Prodcuts, Plastics, port, Product Development, sailing, spinnaker, starboard, Tom Barnes