New Silicone TIR Optic for Outdoor Lighting is Virtually Indestructible

Delivers 91% light transmission without sacrificing durability or performance.

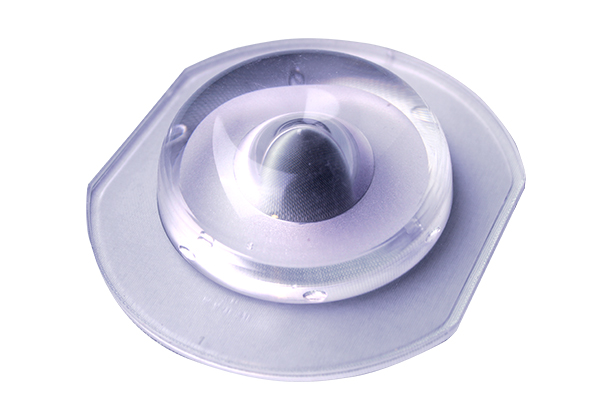

A.L.P. is pleased to introduce the new 1100 Series, a Type V Total Internal Reflection (TIR) optic optimized for COBs with a Light Emitting Surface of up to 18mm. Designed for use in outdoor lighting or other high-power applications, the optical-grade Liquid Silicone Rubber (LSR) optic provides excellent transmittance, impact resistance and high temperature operation while being immune to UV degradation. The 1100 Series offers 65-degree beam distribution, allowing for greater spacing while maintaining uniformity.

Its flange provides mounting features that are compatible with off-the-shelf frames, and bottom side of the optic includes mounting alignment features.

PERFORMANCE HIGHLIGHTS:

“18-V-W”: 18mm LED / type 5 (V) / Wide beam distribution

Designated LED size: 18

Light distribution type: V (5)

Beam description: Wide

FEATURES & BENEFITS

- Excellent uniformity

- Unlimited service lifetime

- Mounting features matching other off-the-shelf optics

- Greater than 91% light transmittance

- Continuous service temperature range -45 to +200º C

- Impact, chemical and UV resistant

In addition to manufacturing the innovative 1100 Series, A.L.P. has unsurpassed capacity and expertise in optical silicone molding. We can produce custom silicone components quickly and cost effectively, in either Charlevoix, MI or Monterrey, MX, with 80-ton, 180-ton, 220-ton, 240-ton and 660-ton press capacities.

Contact your Bill Brown Sales regional manager for more information.

1100 Series, 18mm, A.L.P., COBs, LexaLite, Liquid Silicone Rubber, LSR, optical-grade, Outdoor Lighting, Silicone Optic, TIR Optic

Press Release: A.L.P.® Purchases Key Assets of Sur-Seal Optical Molding Business

(Niles, IL) A.L.P.® has expanded our industry-leading optical silicone molding capabilities by purchasing molding machines and other key assets from Sur-Seal LLC. The equipment is installed in the Charlevoix, MI facility and is operational. As a result, A.L.P. will have six presses capable of molding Liquid Silicone Rubber (LSR) in Charlevoix and has plans to expand this technology to our Monterrey, MX facility in fiscal year 2023. Sur-Seal, in turn, will turn their focus to the core business of producing silicone gaskets.

“A.L.P. sees a great future in optical silicone molding for LED outdoor, industrial and automotive lighting applications,” states Tom Barnes, Vice President and Business Unit Manager. “The opportunity to cooperate with Sur-Seal in this equipment transfer, as they transition out of LSR optics, puts A.L.P. in a strong position to fulfill that emerging demand,” he adds.

A.L.P.’s tie-barless molding machines have advanced production features, including a built-in conveyor, ERC robot, Electro Servo injection, and coining technology. We can currently mold silicone parts up to 200 square inches. This precision silicone equipment, combined with our tooling and optical engineering expertise, makes A.L.P. a superior business partner to quickly take projects from concept to production.

200 Square Inches, A.L.P., automotive lighting, Electro Servo Injection, ERC Robot, Industrial lighting, LED, LexaLite, optical engineering, Optical Molding, Outdoor Lighting, Silicone Molding, Sur-Seal

Press Release: A.L.P. Introduces the Rayder™, a Modern, High-Performance Prismatic Post-Top Sphere

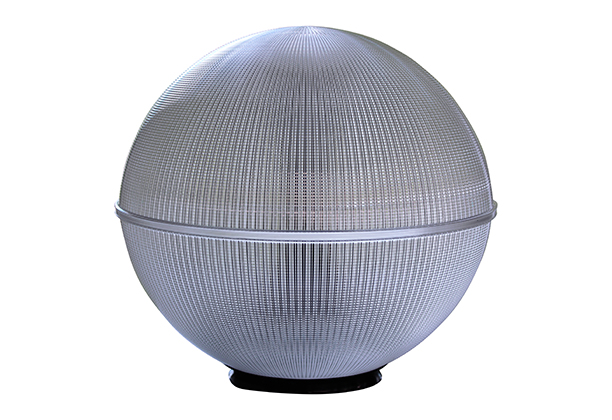

(Niles, IL) -A.L.P. Lighting Components, a leading global manufacturer of lighting components and kits, has added the Rayder™ post-top prismatic sphere to its 400 Series injection molded optics for outdoor lighting. The Rayder is designed to deliver a uniform distribution, higher efficiency, improved CRI, outstanding glare control, and a timeless appearance.

Today’s new post-top installations and retrofits need to be energy efficient, aesthetically pleasing, and provide safe illumination of walkways and streets. The Rayder excels in applications where brightness control is a priority. The Rayder’s optics reduce high angle glare and hide LED light sources while delivering a uniform glowing appearance. The Rayder also offers a significant improvement in efficiency when compared to diffuse or translucent blow molded spheres.

Suitable for 10′ – 20′ poles, the assembled spheres are 19.2″ in diameter, and are available with either 8″ diameter neck or other custom bottom openings. The Rayder is offered in Clear Optical Acrylic, Diffuse Acrylic, and Clear Polycarbonate. The top and bottom halves are easily attached using the affixed UV stable high bond double-sided adhesive ribbon for fast assembly and mounting. Acrylic versions are covered by a ten-year limited warranty.

“Optical glare control and the delivery of IES distributions are paramount features of A.L.P. LexaLite’s post top and dusk-to-dawn refractors,” says Kurt Puffpaff, National Sales Manager for Proprietary Products. “Utilizing A.L.P.’s existing optical prescriptions will increase efficiency, reduce glare and deliver light where light is needed,” he states. “Many fixtures incorporate white or diffuse lenses or no lenses at all. Applying A.L.P.’s optical component will improve fixture performance and application effectiveness,” Puffpaff concludes.

A.L.P. is a leading global supplier of lighting components, offering a diverse line of products and services for lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. offers the industry’s most comprehensive line of LED fixture kits, vapor-proof enclosures, unwired fixture bodies, louvers, and reflectors. A.L.P. Brands include Steel Craft, LexaLite®, and Reflek®

400 Series, A.L.P., Glare Control, High-performance, Injection Molded, LexaLite, Outdoor Lighting, Post-top, Prismatic, Rayder, Sphere, uniform distribution