2026 Trade Show Calendar

A.L.P. will be participating in many major lighting industry events in the coming months. Be sure to stop by to discuss your requirements and applications with our expert team!

Light + Building 2026

March 8-13, 2026

Frankfurt am Main

LEDucation

April 14-15, 2026

New York Hilton Midtown

New York City, NY

IES26 | The Lighting Conference

August 13-15, 2026

Denver Grand Hyatt

Denver, CO

IES Street & Area Lighting Conference

November 8-11, 2026

Sheraton Phoenix Downtown

Phoenix, AZ

7 Things to Know Before You Choose Suspension Hardware

When designing a fixture, it’s easy to focus on performance or looks—but suspension is just as critical. The right suspension ensures safety, simplifies installation, and enhances overall design.

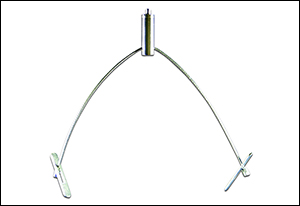

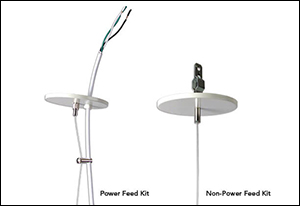

A.L.P. offers a complete portfolio of suspension solutions, including Single-Point, V Hook, Universal Yoke and Toggle, canopy kits, and custom-length tethers. But how do you choose the best option for your project?

Here are seven vital considerations:

- Safety First – Load capacity, strength, and certifications

- Aesthetic Fit – How suspension complements design appearance

- Ease of Installation – Saving time for contractors

- Flexibility & Adjust ability – Accommodating various ceiling heights and fixture weights

- Compatibility – Options including Single-Point, V Hook, Yoke/Toggle, canopy kits, and custom lengths

- Compliance – Meeting UL/ETL requirements and regional standards

- Customization – Tailored solutions with custom tethers and kits

Interested in stronger, safer, smarter fixture suspension?

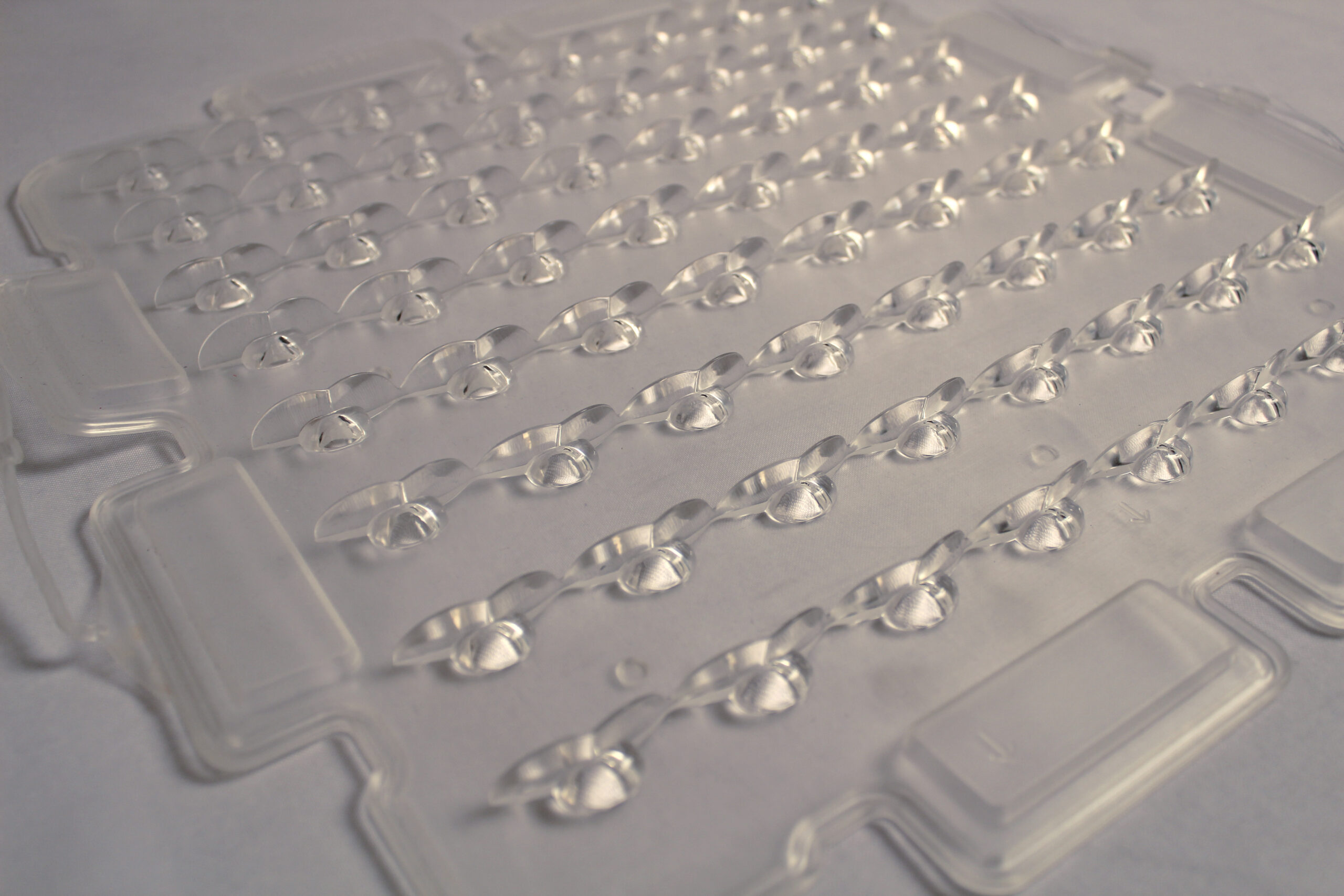

Key Considerations When Choosing a Silicone Molder

Optimizing Optical Silicone Molding for Performance and Efficiency

When selecting a silicone molder for your optical components, several critical factors can impact quality, production speed, and overall cost-effectiveness. A.L.P. brings industry-leading expertise and cutting-edge technology to optical silicone molding, ensuring high precision and rapid turnaround. Here are key considerations to guide your selection process.

Capacity

A.L.P. LexaLite® offers an extensive lineup of seven Liquid Silicone Rubber (LSR) injection molding machines to accommodate projects of various sizes and complexities:

• 80-ton

• 180-ton

• 220-ton

• Three 240-ton

• 660-ton

Advanced Technology

Our state-of-the-art injection molding equipment includes essential production enhancements:

• Built-in conveyor systems for streamlined handling

• Electro Servo injection technology for superior control

Unique Molding Capabilities

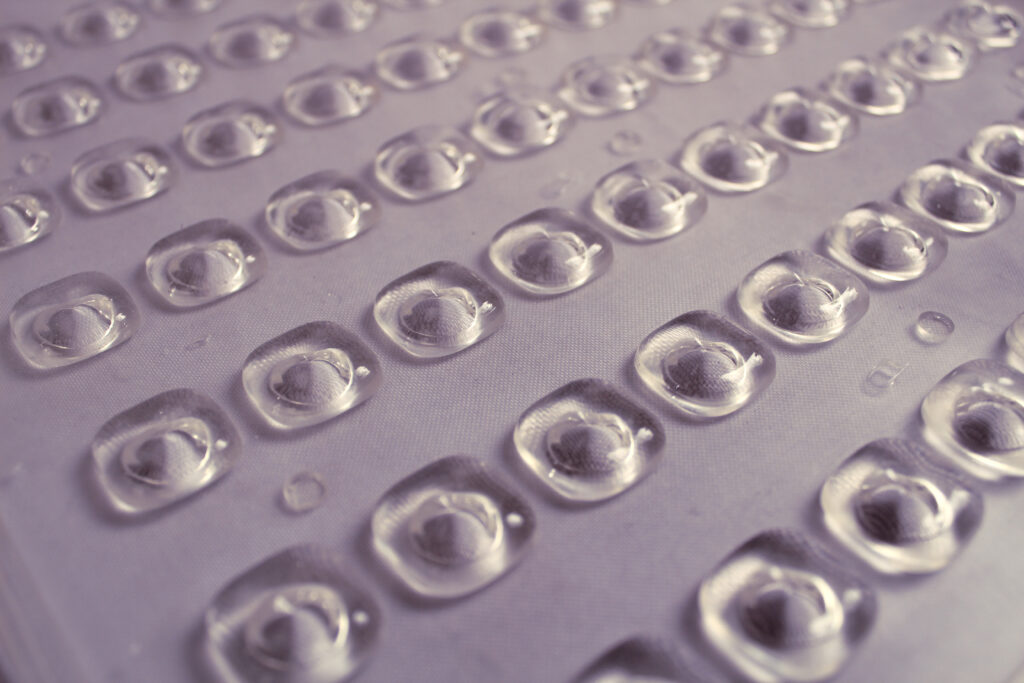

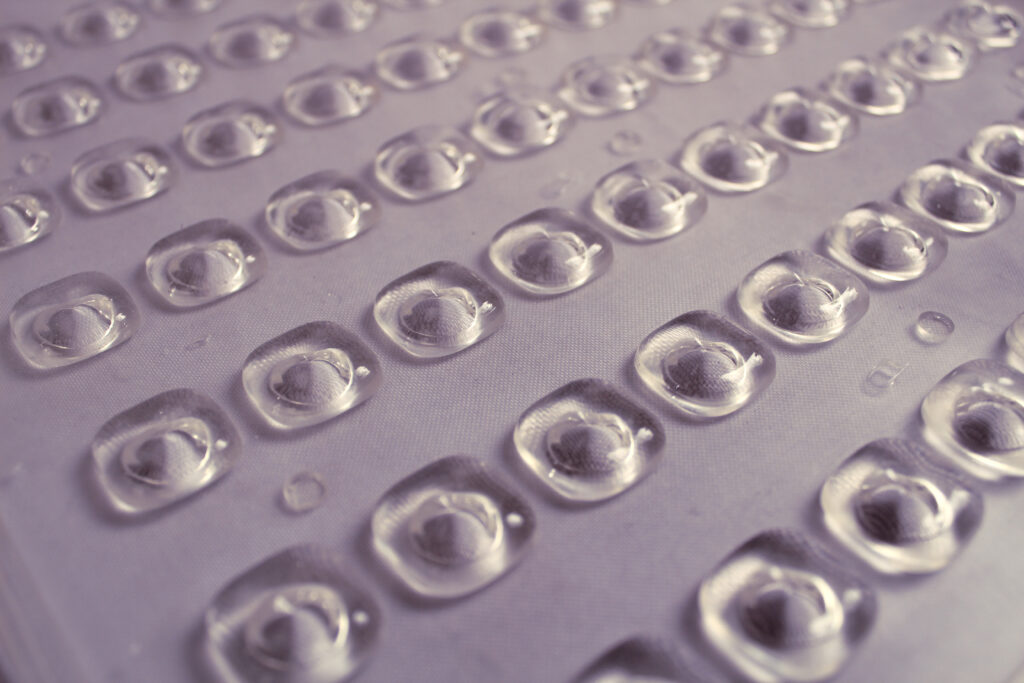

With the capacity to mold parts up to approximately 200 square inches, our equipment is ideal for a wide range of optical applications. The low viscosity of Liquid Silicone Rubber requires molds built with extremely tight tolerances to prevent leaks, ensuring the highest precision in molded components.

In-House Tooling Resources

A.L.P. maintains high-speed machining centers and advanced surface grinding capabilities, allowing us to produce critical tooling in-house. This capability significantly reduces lead times and enhances quality control throughout production.

Rapid Prototyping

Speed to market is crucial in today’s competitive environment. Our precise machining processes minimize the need for extensive polishing, allowing us to produce production-ready inserts in weeks rather than months. This streamlined approach ensures faster prototype iterations and accelerated product development.

Materials Expertise

With over a decade of experience in optical silicone molding, our team has extensive knowledge of LSR materials. We understand the unique molding requirements of optical-grade silicones and engineering molds with the precision necessary to prevent leakage and maintain part integrity.

In-House Testing for Quality Assurance

To guarantee superior product performance, we offer:

• Photometry Lab: Enables real-time evaluation of first-run samples

• Optical Coordinate Measuring Machine (CMM): Ensures molded parts meet precise design specifications

Partner with A.L.P. LexaLite® for Optical Silicone Molding Excellence

With our cutting-edge silicone molding technology, in-house tooling expertise, and commitment to quality, A.L.P. is your ideal partner for bringing optical silicone molding projects from concept to production—quickly and efficiently.

A.L.P. Monterrey Earns ISO 9001:2015 Certification, Enhancing Quality and Value for Customers

A.L.P. is proud to announce that our Monterrey, Mexico manufacturing facility has achieved ISO 9001:2015 certification, a globally recognized benchmark for quality management systems. This certification underscores our unwavering commitment to delivering reliable, high-quality products and services to our customers. For customers across lighting, medical, automotive, appliance, and mass transportation industries, the certification offers added assurance that A.L.P. Monterrey meets rigorous international standards for quality, efficiency, and continuous improvement.

“This is more than a milestone—it’s a reflection of our team’s dedication to operational excellence and our strategic focus on being a trusted partner to OEMs,” states Adam Mayse, A.L.P.’s President and COO.

The Monterrey facility is strategically located in one of Mexico’s key manufacturing corridors, offering proximity to major customers and suppliers. Capabilities at this location include injection molding, compression molding, optical silicone molding, and metal fabrication.

Congratulations to the entire Monterrey team for their hard work and focus in achieving this important certification—another step forward in strengthening A.L.P.’s value to our customers.

Why Silicone is Revolutionizing Optical Molding

In the world of precision optics, choosing the right material for your molding project can significantly impact performance, durability, and efficiency. Optical silicone molding is emerging as a game-changer, offering advantages that surpass traditional thermoplastics. A.L.P. provides industry-leading expertise in optical silicone molding, combining advanced equipment, tooling, and optical engineering to deliver high-quality solutions. Our in-house photometry lab enables real-time evaluation of first samples, ensuring optimized results from concept to production.

The Advantages of Optical Silicone Molding

When selecting materials for optical applications, Moldable Optical Silicone (MOS) stands out due to its unique properties. Here’s why optical silicone is revolutionizing the industry:

Superior Optical Clarity and Light Transmission

• Optical silicone provides greater than 91% light transmittance, ensuring maximum efficiency in lighting and optical applications.

• A refractive index of 1.41, it enables high-performance optical designs.

Exceptional Moldability and Precision

• Its low viscosity allows for excellent mold replication, capturing fine details with precision.

• Unlike thermoplastics, silicone requires low clamp tonnage, reducing production costs and complexity.

• Negative draft (undercut) features can be achieved with optical silicone, making it highly versatile for complex geometries.

Unmatched Durability and Environmental Resistance

• Silicone offers an exceptional continuous service temperature range from -45°C to +200°C, maintaining stability in extreme conditions.

• Most optical silicone grades are immune to UV degradation, ensuring long-lasting performance without yellowing or material breakdown.

• Exceptional impact resistance makes it ideal for rugged applications.

Versatility in Molding and Integration

• Insert molding capabilities with plastic, metal, and glass allow for integrated component manufacturing.

• Silicone expands when molded, allowing for thicker wall sections with no sink marks, a common issue with thermoplastics.

• Its ability to provide self-gasketing and self-mounting functionalities reduces the need for additional components and assembly steps.

Why Choose A.L.P. for Optical Silicone Molding?

A.L.P. stands at the forefront of optical silicone molding, leveraging cutting-edge equipment, innovative engineering, and a dedicated in-house photometry lab. Our expertise ensures:

• Rapid prototype development and testing

• Precision molding with complex geometries

• Reliable, high-performance optical solutions for demanding applications

If you’re considering optical silicone molding for your next project, A.L.P. is your trusted partner. Contact us today to learn how we can help bring your vision to life with industry-leading silicone molding solutions.

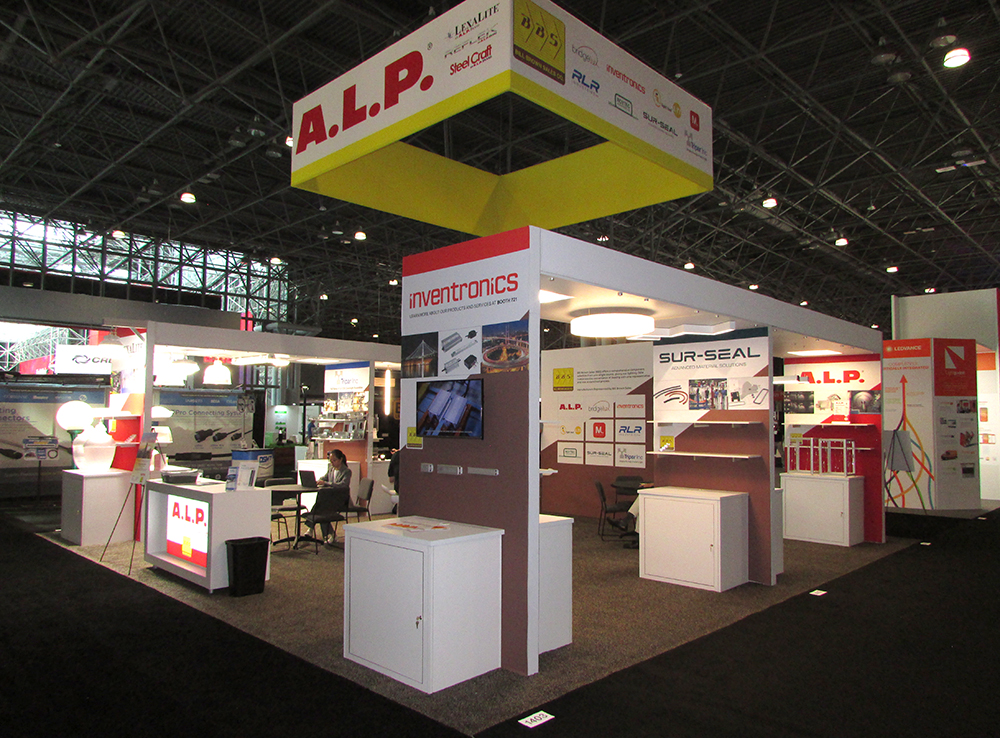

Meet A.L.P. at 2025’s Top Lighting Trade Shows!

See You at the Show!

A.L.P. is excited to showcase our extensive catalog of lighting components and custom manufacturing capabilities at several premier U.S. lighting industry trade shows in 2025.

We understand the importance of in-person interactions. Before investing in components for your fixture design, it’s essential to see them, test them, and ensure they meet your exact objectives. Similarly, when selecting a partner for custom-molded optical components or fabricated metal parts, sitting down with manufacturing experts is key to building trust and confidence.

With corporate travel budgets tighter than ever, making the most of your time and resources is critical. That’s why the A.L.P. team is committed to maximizing the value of your trade show visits. We’re bringing our best innovations and brightest experts to these industry-leading events:

LEDucation | March 18–19, 2025 | New York, NY

Lightfair International | May 4–8, 2025 | Las Vegas, NV

IES25—The Lighting Conference | August 21–23, 2025 | Anaheim, CA

IES Street and Area Lighting Conference | September 21–24, 2025 | New Orleans, LA

We’d love to connect with you at these shows! Visit our booth to explore our products, meet our team, and discover how we can support your projects. To ensure dedicated time with us, contact your regional sales manager to schedule a one-on-one appointment. If you’re planning to attend, let A.L.P. help make your trip worthwhile!

A.L.P. is a leading global supplier of lighting components, providing a diverse portfolio of products and services tailored to the needs of lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. delivers the industry’s most comprehensive range of optical components, LED fixture kits, custom services, and more. With over 40 years of experience, A.L.P. continues to set the standard for quality and innovation. The company’s premier brands, including LexaLite® and Steel Craft, are trusted worldwide for their performance and reliability.