Key Considerations When Choosing a Silicone Molder

Optimizing Optical Silicone Molding for Performance and Efficiency

When selecting a silicone molder for your optical components, several critical factors can impact quality, production speed, and overall cost-effectiveness. A.L.P. brings industry-leading expertise and cutting-edge technology to optical silicone molding, ensuring high precision and rapid turnaround. Here are key considerations to guide your selection process.

Capacity

A.L.P. LexaLite® offers an extensive lineup of seven Liquid Silicone Rubber (LSR) injection molding machines to accommodate projects of various sizes and complexities:

• 80-ton

• 180-ton

• 220-ton

• Three 240-ton

• 660-ton

Advanced Technology

Our state-of-the-art injection molding equipment includes essential production enhancements:

• Built-in conveyor systems for streamlined handling

• Electro Servo injection technology for superior control

Unique Molding Capabilities

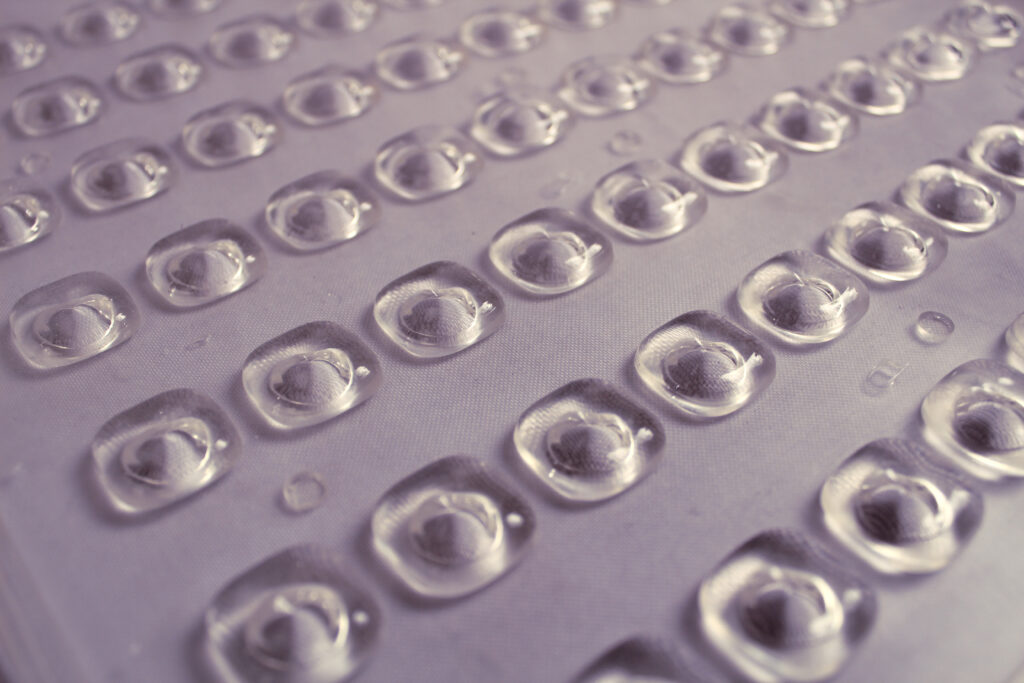

With the capacity to mold parts up to approximately 200 square inches, our equipment is ideal for a wide range of optical applications. The low viscosity of Liquid Silicone Rubber requires molds built with extremely tight tolerances to prevent leaks, ensuring the highest precision in molded components.

In-House Tooling Resources

A.L.P. maintains high-speed machining centers and advanced surface grinding capabilities, allowing us to produce critical tooling in-house. This capability significantly reduces lead times and enhances quality control throughout production.

Rapid Prototyping

Speed to market is crucial in today’s competitive environment. Our precise machining processes minimize the need for extensive polishing, allowing us to produce production-ready inserts in weeks rather than months. This streamlined approach ensures faster prototype iterations and accelerated product development.

Materials Expertise

With over a decade of experience in optical silicone molding, our team has extensive knowledge of LSR materials. We understand the unique molding requirements of optical-grade silicones and engineering molds with the precision necessary to prevent leakage and maintain part integrity.

In-House Testing for Quality Assurance

To guarantee superior product performance, we offer:

• Photometry Lab: Enables real-time evaluation of first-run samples

• Optical Coordinate Measuring Machine (CMM): Ensures molded parts meet precise design specifications

Partner with A.L.P. LexaLite® for Optical Silicone Molding Excellence

With our cutting-edge silicone molding technology, in-house tooling expertise, and commitment to quality, A.L.P. is your ideal partner for bringing optical silicone molding projects from concept to production—quickly and efficiently.

A.L.P., In-house Tooling, injection molding, LexaLite, Liquid Silicone Rubber, LSR, Moldable Optical Silicone (MOS), Optical Silicone, Rapid Prototyping, Silicone Molder